Step-By-Step Guide to Research and Development of Mechanical Press

The research and development of a mechanical press is a complex process. It involves many different steps, which must be followed in the right order. This guide will show you how to research and develop your own mechanical press.

Introduction To Research and Development of Mechanical Press

Let’s talk about the research and development of mechanical press together. Mechanical presses are one of the most essential tools in any metal forming operation. They are used to perform a variety of operations including punching, shearing, forming, and stamping.

Mechanical presses are often referred to as sheet metal forming equipment. The term sheet metal is used to describe flat pieces of metal that have been formed into certain shapes or dimensions by mechanical means.

Although mechanical presses have been around for hundreds of years, it wasn’t until recently that they became more popular in the manufacturing industry. This is due to their ability to automate repetitive tasks that were previously done manually by hand.

A mechanical press can be used to manufacture products with high pressure, low weight, and high quality. The main purpose of these machines is to reduce costs and increase productivity.

What Are Mechanical Presses And Their Use?

A mechanical press is a machine that uses force to apply pressure onto metal. It is used to shape and form different materials, such as sheet metal, but it can also be used to roll out thin sheets of plastic or rubber.

Mechanical presses are made up of several components. The components include the barrel and the die, which are fitted together so that they can move against each other. These movements cause the parts to be pressed or moved in order to form the desired shape or design on the surface of the material being formed.

The best mechanical presses are strong and durable, but they also need to be easy to use. For example, if you want to press a sheet of metal into shape and then roll it up again, you might want to use a hydraulic press. This type of press has an attached cylinder that takes some of the weight off your hands while working with it.

A mechanical press is not just for metal though; it can also be used for making other materials like plastics or rubber. If you want to make something like rubber flooring or even jewelry, a mechanical press is probably the best tool for the job!

What Does a Typical Mechanical Press Look Like?

The term “mechanical press” refers to a machine that uses one or more mechanical forces to exert pressure on the forming part. There are many different types of mechanical presses, but all machines have in common the use of force to deform or deform the workpiece being formed by the machine.

A typical mechanical press will have at least two cylinders (or a ram) that move back and forth. The cylinders may be fixed, which means they do not move during operation, or they may be adjustable so that they can be raised and lowered during operation. This allows for different depths of penetration into the workpiece by each cylinder for different materials, such as sheet metal or plastic.

There are several other components on most mechanical presses, such as hydraulic systems for moving parts, feed mechanisms for controlling material flow through the machine, and metering devices for measuring how much material is being fed into the machine at any given time. Most mechanical presses also include air compressors that provide the air pressure required for operating various components of the machine.

What Can Kind Of Material Be Forged In a Mechanical Press?

The mechanical press can be used to forge all kinds of materials. The key is to make sure that the material being forged is of the right size and shape, as well as being heated to the right temperature.

There are many different types of metals that can be forged in a mechanical press. Some of the most common include mild steel, cast iron, stainless steel, and aluminum. Most metals can be forged into different shapes and sizes by using a variety of tools in the press.

For example, if you want to forge steel, then you need a suitable steel source. This could be an ingot or block of steel or even a bar or rod that has been formed into a shape suitable for forging. You then need to heat up your material with some sort of heating mechanism in order for it to melt and flow into the mold (in this case, your die).

Once the material has been heated up and formed into shape, it can then be placed in the die and pressed against another piece of material (called a blank) in order for them both to fuse together and become one single piece.

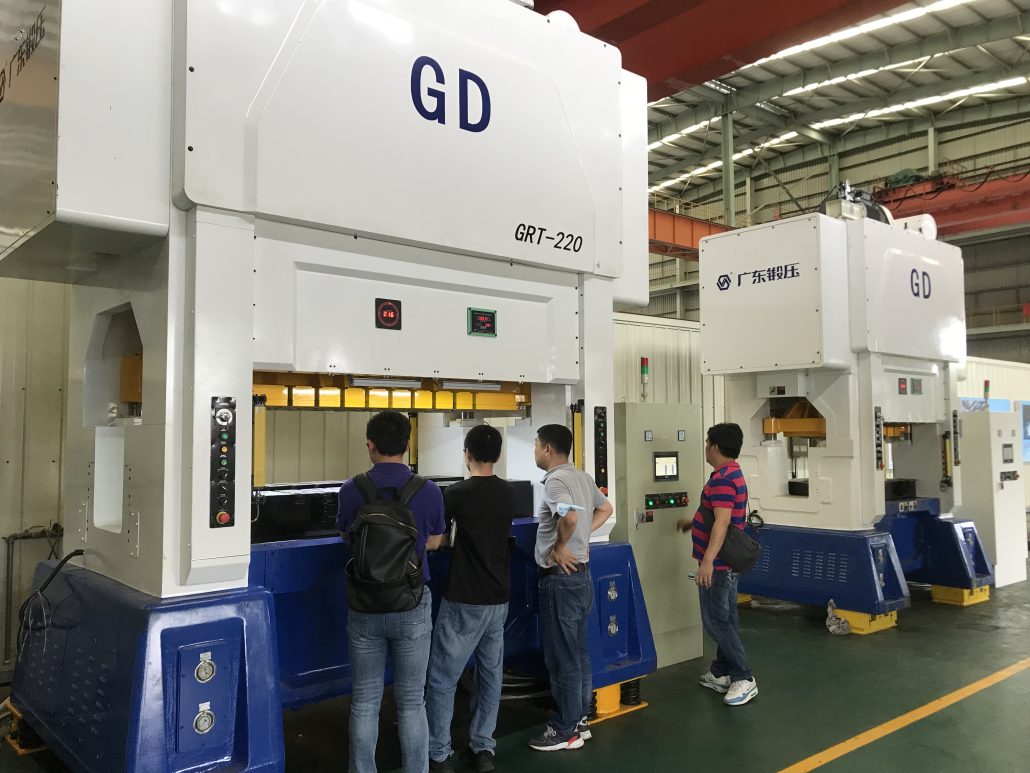

GuangDuan Customized Design Mechanical Presses Solutions for Your Business

GuangDuan is a manufacturer of mechanical presses, hydraulic presses, and other machine tools in China. We can provide you with high-quality products and services at competitive prices.

Our main products are mechanical presses, hydraulic press machines, forge presses, and high-speed presses. In many years of development, we have devoted ourselves to providing high-quality products and services to our customers all over the world.

With more than 65 years of experience in this industry and many years of production experience, our team sets up a team of experts to provide solutions customized to your needs. With high-quality products and professional service, GuangDuan will be your reliable partner to help you meet all your pressing needs!

Concluding Remarks

GuangDuan Mechanical Presses are designed with high-quality parts and components to ensure long-term reliable operation and performance. Our equipment is flexible, simple to operate and install, with excellent productivity. They can provide strong trusses at the same time.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us