PRODUCT

Hydraulic and Mechanical Press Machine Manufacturer

High tension cast iron and internal stress relief ensure precision, high stability and great ability of shock resistance of Guangduan’s high speed presses. Our forging presses are mainly applied in rotor, stator and those metal parts that in extreme demand of effective productivity.

WHY CHOOSE US

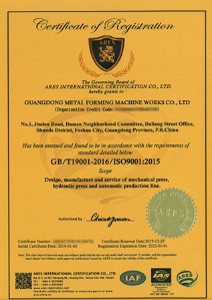

Founded in 1958, with more than 60 years experience in developing cutting-edge technology in metal stamping, GUANGDUAN has become the largest forging and press machine manufacturer in Southern China. It integrates R&D, manufacturing, and service of hydraulic press machines, mechanical press machines, and forging press. Also it is known as a national high-tech enterprise and one of the fifty backbone press machines enterprises in Guangdong province. With over 800 experienced employers, a large quantity of advanced processing and inspection equipment and a principle of serving customers wholeheartedly, we keep forging ahead towards providing metal stamping solutions and service to customer satisfaction.

SOME FUN FACE ABOUT OUR BUSINESS

Industrial Experience

Facility Size

Engineers & Technicians

Production Equipment

CASE

An automated servo hydraulic press machine production line composed of 12 large gantry servo hydraulic press machines with specifications of 12000kN, 8000kN and 6300kN are completed on time and customer’s quality target, with our team’s concerted efforts and working hard.

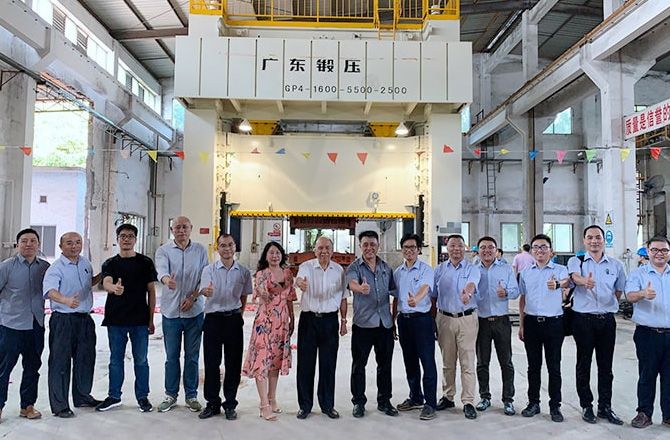

GP4-1600-5500-2500 straight side four-point precision mechanical press machine provides efficiency production capacity for large-scale automobile parts toolings.

800T H-type hydraulic servo press testing with tooling for washing machine before painting and shipment

Warmly celebrate the successful delivery of GP2-1000 and GD2-800 mechanical press machines for the production of large-scale automotive metal parts

NEWS

You can get the latest industry information from here.

Servo Hydraulic Press Explained: How Eight-Sided Guides Ensure Precision

30/01/2026

A servo hydraulic press is only as precise as the way its slide is guided. At Guangduan, we design presses for shops that need consistent, repeatable forming every shift. In this article, we explain how eight-sided guides stabilize the slide, how closed-loop servo control improves accuracy and efficiency, and why structure, lubrication, and safety features ... Read more

Mechanical Stamping Equipment for EU Data Centers: STPP Series Insights

29/01/2026

Efficient hardware is part of Europe’s digital footprint. Mechanical stamping for EU data centers is now a core function, delivering precise chassis, racks, busbars, and cabinets with minimal variation. With rising density and stricter sustainability criteria, specifying the right equipment protects quality, energy targets, and delivery schedules. The stakes are high. EU data centers need ... Read more

2026 Metal Stretch Forming Machine: Aligning, Bending, Folding Explained

28/01/2026

By 2026, the metal stretch forming machine marks the beginning of a new chapter in sheet forming. It aligns, bends, and folds thin steel and aluminum with disciplined control. Efficiency rises; tolerances tighten. Yet the crucial mechanisms remain concealed. Which forces, paths, and fixtures govern repeatability? What breakthroughs guide this change? Quality and cost considerations ... Read more

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us