-

Home / TECHNICAL ADVANTAGES

TECHNICAL ADVANTAGES

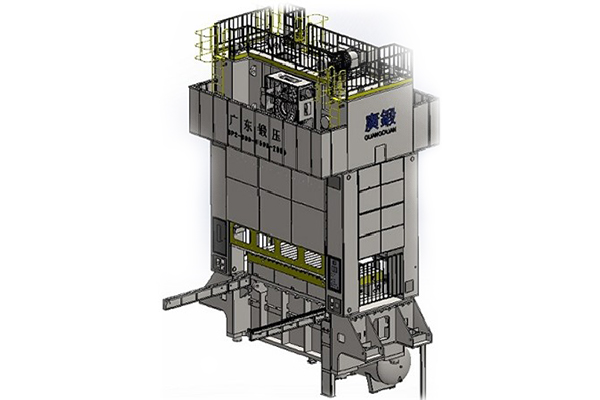

1. Three Dimensional Design

Adopt international high-end design software and data management system to build a perfect digital R&D platform.

We fully adopt SOLIDWORKS 3D software for product development, subdivide products by functional components, adopt modularization, serialization and generalization design concepts to speed up design response, improve design quality, optimize product costs and improve product market competitiveness.

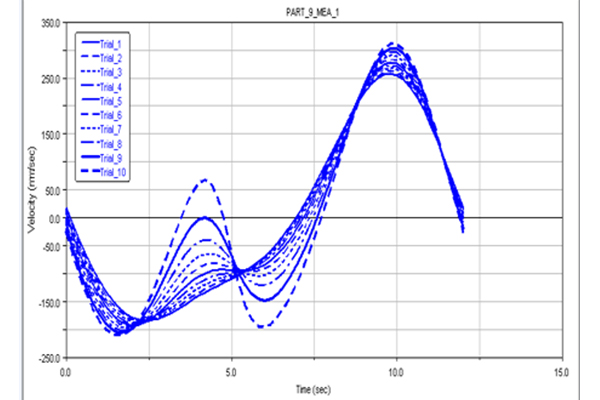

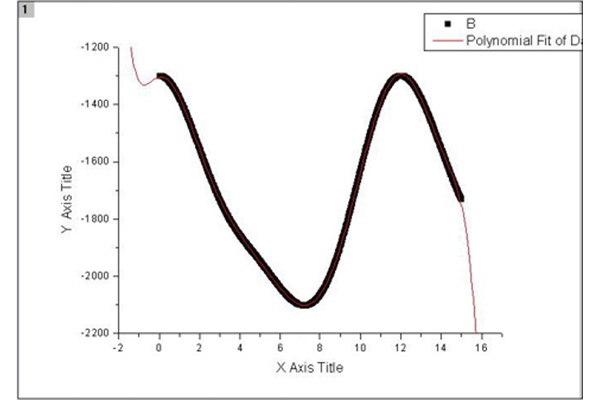

Taking advantage of the regional advantages, we have cooperated closely and deeply with the R&D teams of universities such as South China University of Technology and Guangdong University of Technology, especially developing software related to rod system optimization, accuracy analysis, and dynamics analysis for multi-link presses.

Eight-link Mechanism

Rod System Analysis

Motion Fitting

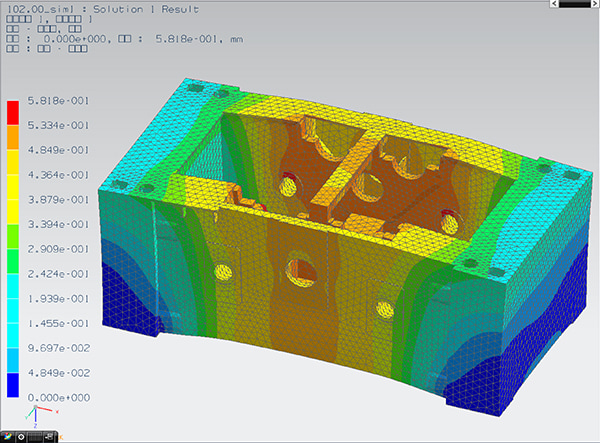

ANSYS finite element analysis software is used to analyze the force of the main welding parts, optimize the structure of the welding parts, improve the rigidity and accuracy of the whole machine, and ensure that the press can maintain good accuracy even after long-term stamping operation.

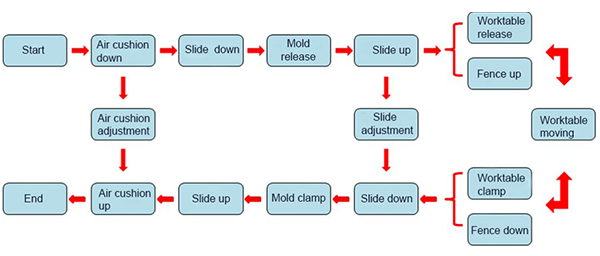

Large presses can realize one-touch quick die change technology, the shortest die change time is less than 3 minutes, which increases production efficiency, improves workers’ working environment and enhances factory intelligence.

Quick Mold Change Flow Chart

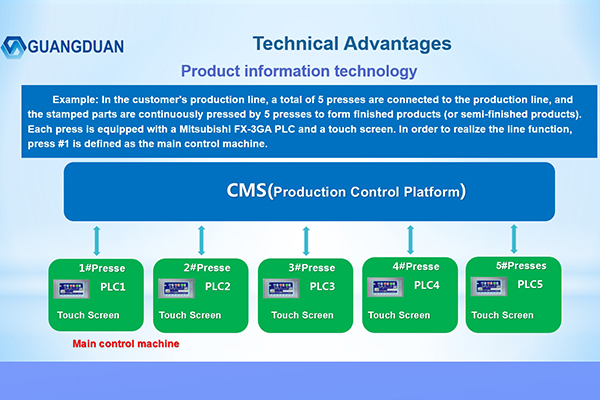

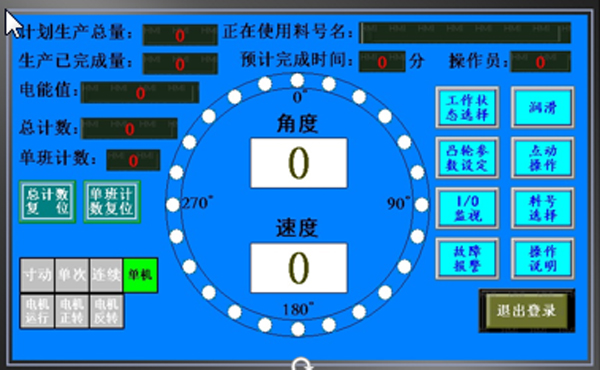

2. Product Information Technology

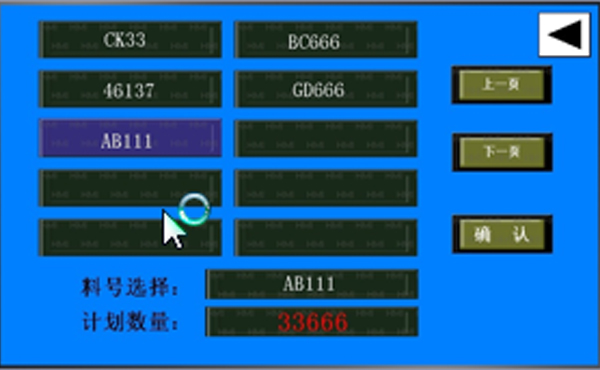

Example: In the customer’s production line, a total of 5 presses are connected to the production line, and the stamped parts are continuously pressed by 5 presses to form finished products (or semi-finished products). Each press is equipped with a Mitsubishi FX-3GA PLC and a touch screen. In order to realize the line function, press #1 is defined as the main control machine.

Product communication, in addition to the wide forging CMS system networking, also can cooperate with the customer’s MES system to provide their required equipment status data exchange of data.

EQUIPMENT ADVANTAGES

Welding Robot

The welding workshop uses welding robots to automatically weld large parts.

Maximum Weight of Workpiece: 30 tons

Effective Travel: X-axis: 6000 mm, Y-axis: 2000 mm, Z-axis: 1500mm

Maximum Length of Workpiece: 10000mm

Large Chamber Type Rotary Table Shot Blasting Machine

Inner Volume of Shot Blasting Machine: φ7000×H 5500

Maximum Weight of Workpiece: 80 tons

Annealing Furnace Volume: W3600×H5500×D8000

Large Annealing Furnace

Inner Volume of Shot Blasting Machine: φ7000×H 5500

Maximum Weight of Workpiece: 80 tons

Annealing Furnace Volume: W3600×H5500×D8000

Medium Frequency Induction Heating Equipment

Maximum Length of Quenched Workpiece: 2400mm

Maximum Diameter of Quenched Workpiece: 500mm on spindle

Worktable: 2000mm

Maximum Weight of Quenched Workpiece: 1500kg

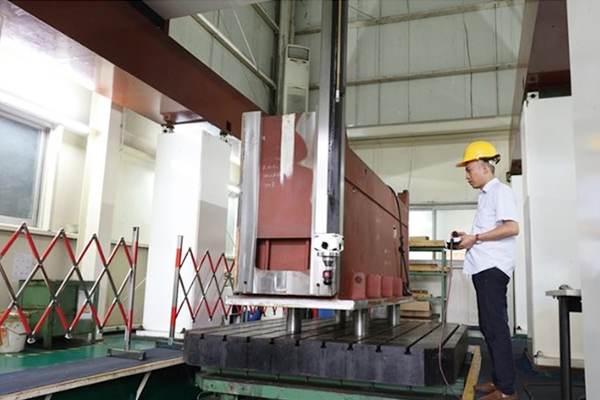

Large-sized CNC Boring and Milling Machine

Using large CNC floor boring and milling machine to process the upper beam of the press.

Spindle Diameter: 250mm

Spindle X-direction Displacement: 4150mm

Spindle Y-direction Displacement: 8000mm

Size of Working Table: 4000×4000mm

Large CNC Moving Beam Gantry Boring and Milling Machine

Large CNC gantry boring and milling machine is used to process large parts.

X-axis Travel: 12500mm

Y-axis Travel: 5800mm

Gantry Width: 4600mm

Table Size: 4000×12000mm

Large CNC Gantry Type Milling and Boring Machine

The use of large CNC gantry boring and milling machine processing base.

Table Plate Table Width: 2500mm

Length of Working Table: 15000mm

5m Digital Control Crane

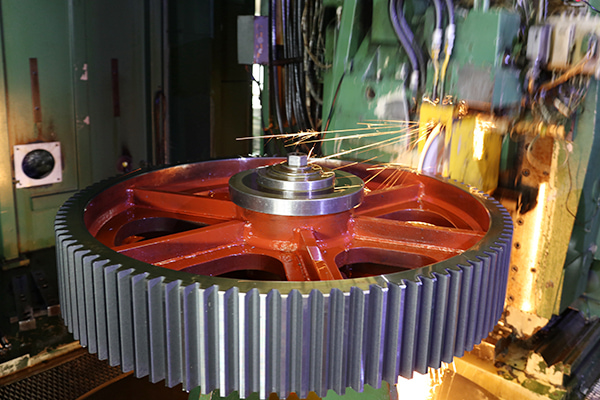

Machining of eccentric gears and large flywheels with large CNC vertical lathes.

Maximum Rotating Diameter: 5000mm

Maximum Processing Height: 3150mm

Max. Working Weight: 32 tons

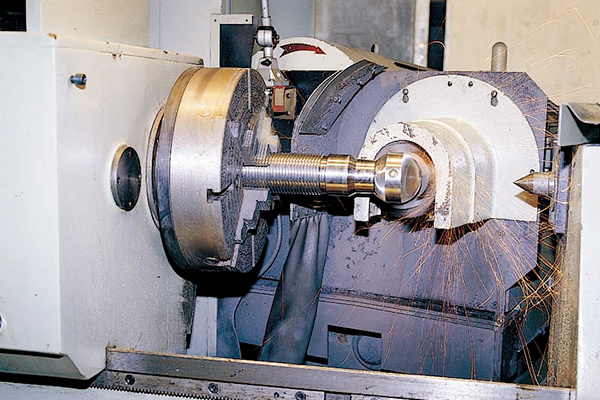

CNC Heavy-duty Horizontal Lathe

Maximum Swing Diameter on Bed: Φ2000mm

Maximum Rotation Diameter of Over Tool Holder: Φ1600mm

Max. Workpiece length: 12000mm

Max. Workpiece Weight: 20t

CNC Lathe

Max. Cutting Diameter: 0 ~1000mm

Maximum Longitudinal Stroke: 1255 ~3000mm

CNC Gantry Type Surface Grinding Machine

Precision grinding of guide rails and table planes.

Width of Working Table: 2500mm

Table Length: 6000mm

Maximum Longitudinal Travel of Table: 6000mm

Max. Grinding Workpiece Size (L×W×H): 6000×3050×1200mm

German Gear Grinding Machine

Precision grinding of gears by CNC gear grinding machine.

Max. Workpiece/Diameter: 2500mm

Max. Module of Workpiece: 25mm

Maximum/Minimum Mumber of Teeth to Be Added: 250/10

Max. Worktable Weight: 4000kg

CNC Ball Head Grinding Machine

The nitride ball screw is precision ground by a special ball grinding machine and thread grinding machine.

Max. Workpiece Diameter: 320mm

Max. Workpiece Length: 1000mm

Max. Diameter of Threads That Can Be Ground: 300mm

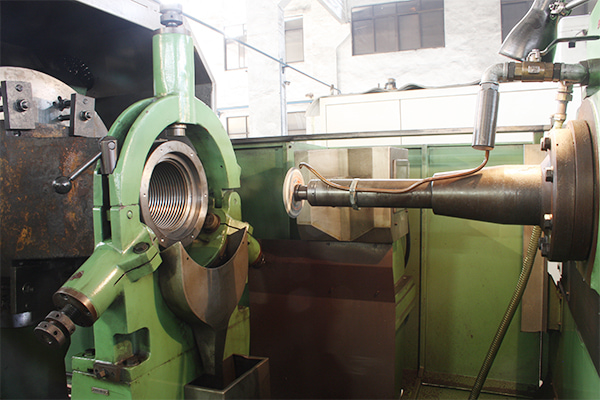

CNC Internal Screw Grinding Machine

Max. Grinding Internal Thread Diameter: 200mm

Max. Workpiece Length: 1000mm

Deep Hole Internal Grinding Machine

Internal thread grinding by deep hole internal grinding machine.

Max. Workpiece Diameter: 400mm

Max. Grinding Depth: 1100mm

CNC Crankshaft Grinding Machine

Crankshaft grinding by crankshaft grinding machine.

Maximum Rotary Diameter: 1000mm

Max. Workpiece Length: 6000mm

QUALITY CONTROL

Italy Coordinate Measuring Machine

Measuring Range: 5m long * 2.5m wide * 2.5m high

Maximum Load Weight: 45 tons

Measuring Accuracy: ±0.004mm

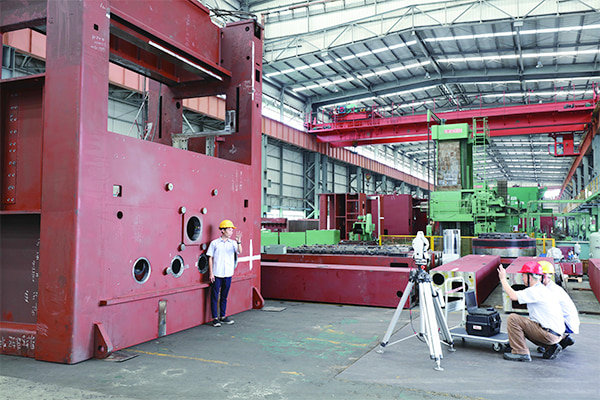

Swiss Laser Tracker

The Detection Accuracy Reaches: 15um±6um/m

It is the highest precision laser tracker at present.

Various Types of Precision Testing Instruments

Ultrasonic Detector

Italy Coordinate Measuring Machine

Swiss Laser Tracker

Ultrasonic Detector

Richter Hardness Tester

Richter Hardness Tester

Dynamic Balance Testing, Adjustment

Lower Dead Center Checker

Vibrometer

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us