High-Performance Stamping Press for Large Parts Production | Precision & Efficiency

Why are stamping presses important in industrial manufacturing? They shape metal parts with speed and accuracy. Many industries use them to produce parts in large numbers.

Now, there is a new high-performance stamping press – GD2. It is designed for better efficiency and precision. The main parts, like the machine body and slide, are made by welding strong steel plates. This gives the machine good strength. Models with a capacity above 600 tons have a split machine body and a pull lever structure. This design makes moving and setting up the machine easier.

Industry Need for Advanced Stamping Technology

Growing Demand for Large, High-Quality Metal Parts

Many industries, like automotive, aerospace, and heavy machinery, need large and strong metal parts. These industries produce a high number of parts every day. So, they need machines that work fast and with great accuracy. Traditional stamping presses cannot always meet these needs. That is why there is a demand for better stamping technology.

Challenges with Traditional Stamping Presses

Traditional stamping presses have some problems. First, they are not always fast enough for large-scale production. Second, they may not be precise, which can cause defects in the parts. Third, they use a lot of energy, which increases costs. Because of these issues, manufacturers are looking for new stamping presses that are stronger, faster, and more efficient.

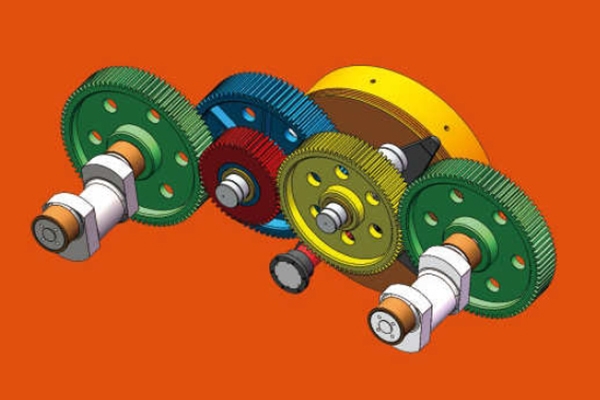

Multi-Station Transmission Device

Better Load Capacity with Two-Level Gear Transmission

The machine uses a two-level gear transmission. It also has an extra idler mechanism in the middle. This setup increases the space between pressure points. As a result, the machine can handle higher loads. This is important for multi-station and progressive die stamping because it creates heavy eccentric loads.

Compact Structure and Space-Saving Design

This transmission system helps lower the machine’s total height. Because of this, the machine is more compact. It also takes up less space in the factory. So, manufacturers can fit more machines or other equipment in the same area.

Suitable for Large Work Tables

The design of this structure makes it perfect for wide work tables. It also works well for multi-station dies, which allow stamping multiple parts in one operation.

Eight-Surface Full-Guideway Guiding

Stronger Resistance to Unbalanced Loads

The slide uses an eight-surface full-guideway guiding system. This gives it better resistance to unbalanced loads. When the load is not evenly distributed, the machine stays stable and performs well.

Higher Precision and Longer Lifespan

The guiding system reduces side forces. Because of this, the machine maintains high precision over time. It also improves durability, so the machine can last longer without losing accuracy.

High-Torque Wet-Type Clutch

Large Torque and Long Lifespan

This stamping press uses an oil-filled wet-type clutch. The clutch has strong friction plates, which create large torque. It also lasts a long time, so it does not wear out quickly.

Fast and Stable Operation

The clutch has a multi-plate, low-inertia design. Because of this, the machine starts and stops quickly. It also connects smoothly, which makes the stamping process stable.

Ideal for Continuous Production

The clutch allows many start-and-stop operations. Because of this, it is perfect for continuous production lines. Operators can stop and restart the machine as needed without losing efficiency.

Low Noise and No Pollution

This clutch design does not create much noise. It also does not release pollutants. Because of this, it meets environmental standards and makes the workplace safer.

Upper and Lower Die Cushions for Multi-Station Press

High Force in a Small Size

The die cushions provide strong force while being small in size. This makes them ideal for different step distances in the stamping process.

Long Lifespan and High Precision

These die cushions last a long time. They also maintain high precision over many uses. So, manufacturers can rely on them for consistent results.

Fast Response and Stable Pressure

The die cushions react quickly to changes. Their pressure stays stable, so the stamping process runs smoothly.

Independent Pressure Adjustment

Each die cushion’s pressure can be adjusted separately. This allows greater control over the stamping process. Manufacturers can set different pressures for different stages of production.

Benefits for Manufacturers

Higher Productivity

This stamping press works fast and accurately. So, manufacturers can produce more parts in less time.

Less Material Waste and Fewer Errors

Because the machine is precise, it reduces material waste. It also minimizes defects, so fewer parts need to be remade.

Lower Costs Through Efficiency and Durability

The machine is designed to be energy-efficient. It also has a long lifespan. These features help reduce costs for manufacturers.

Versatile for Different Materials and Complex Shapes

This stamping press can handle different types of metals. It also works well for complex part designs. So, manufacturers can use it for a wide range of products.

Find the Perfect Stamping Press for Your Needs!

A powerful and efficient stamping press is essential for high-quality production. It ensures precision, speed, and durability – key factors for industries looking to stay ahead in the market.

Designed for superior performance, this high-end stamping press features a robust steel frame and advanced technology. It effortlessly handles heavy loads and works with various metals while optimizing space and minimizing waste. Its smooth, quiet, and durable clutch system, combined with a precision-guided mechanism, guarantees long-term accuracy and reliability.

Manufacturers need fast, dependable machines to enhance productivity and reduce costs. This stamping press does just that – boosting efficiency while maintaining exceptional quality.

Upgrade today and take your production to the next level. Maximize efficiency, cut costs, and achieve outstanding results with the right stamping press!

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us