Heavy Stamping Machinery: Precision and Power for Industrial Manufacturing

What is High-Precision Heavy Stamping Machinery?

High-precision heavy stamping machinery is important in modern manufacturing. But what makes it special? First, the machine body is made by welding steel plates. After that, it goes through high-temperature annealing. This process makes it strong and keeps its precision stable.

Also, the machine has a self-moving work table and a die clamping system. Because of this, die changes become faster and easier. As a result, production efficiency improves.

Why does this matter? Many industries need precision metal forming. The demand is growing because products must be more accurate and consistent. So, high-precision heavy stamping machinery plays a key role in meeting these needs.

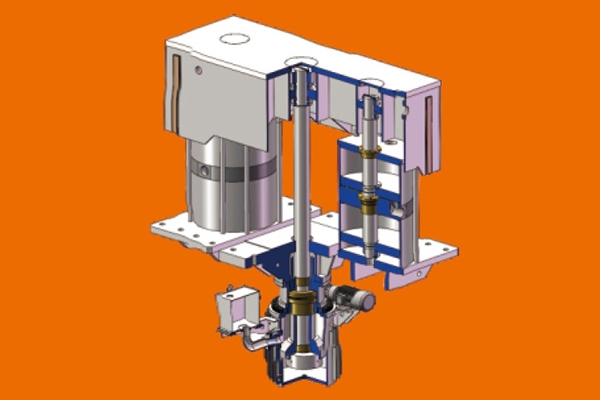

Key Features of Two-Point/Four-Point Single Acting Mechanical Presses

Machine Body

The machine body is constructed using high-quality welded steel plates, followed by high-temperature annealing. This meticulous process enhances structural strength, prevents deformation, and ensures long-term precision stability. The rigid framework effectively absorbs vibrations during operation, extending the lifespan of the press and improving safety.

Work Table and Die Clamping System

A self-moving work table, combined with a die clamping system, streamlines die changes, significantly reducing downtime. This setup enhances operational efficiency and minimizes manual intervention, leading to faster production cycles. The die clamping system is designed for versatility, accommodating various die sizes and configurations, making the press adaptable for diverse manufacturing needs.

Slide and Guideway

The slide operates on an advanced eight-surface long guideway, ensuring precision stability and steady production. This design minimizes lateral movement and enhances the accuracy of each press stroke. As a result, the machine produces high-quality stamped components with consistent dimensions, reducing the need for secondary machining.

Air Cushion System

The machine incorporates a high-tonnage air cushion that utilizes pure gas to meet a wide range of blank pressing and ejection requirements. This feature optimizes material flow and blank holding, improving forming accuracy and reducing material waste. The air cushion system is especially beneficial for complex forming operations that demand controlled force application.

Main Transmission Structure

The main transmission system consists of five precisely arranged shafts moving in different directions, with symmetrically placed gears. This intelligent design reduces gear inertia force and minimizes side forces on the connecting rod, leading to superior precision and stability.

The five-shaft configuration increases the distance between left and right pressure points, enhancing the machine’s load-handling capacity and allowing it to withstand higher operational forces.

The transmission system operates through a two-level speed reduction mechanism:

- High-speed level: Utilizes a herringbone gear for smooth operation and increased efficiency.

- Low-speed level: Employs a straight gear for superior torque transmission.

To ensure durability and performance, the small gear is made from high-strength alloy steel, while the large gear is crafted from NO.45 forged steel. Advanced heat treatment processes regulate hardness variations, significantly improving wear resistance and extending service life.

The entire transmission gear assembly, including the connecting rod, is enclosed in a sealed beam. Given that these gears function under heavy loads at low speeds, an automatic thin-oil lubrication system is integrated to reduce wear, minimize noise, and enhance reliability.

Advanced Features of the Air Cushion System

Structural Components

The air cushion system is a high-performance, single apical cap, pure gas type design, consisting of:

- Apical cap for precise force distribution.

- Two main cylinders that provide balanced pressure.

- Stroke regulating mechanism to customize stroke length for various operations.

- Buffering mechanism to minimize impact and enhance operational smoothness.

- Lag latching cylinder (optional) for specialized forming processes requiring precise hold control.

Stroke Regulation and Efficiency

The air cushion system includes a stroke-regulating device with a standard-length ejector rod. This feature eliminates the need for frequent rod replacements, significantly improving efficiency and reducing setup time. The adjustable stroke accommodates different drawing processes, making the machine highly adaptable for various stamping applications.

Hydraulic Terminal Buffering

To enhance operational smoothness and reduce mechanical stress, the air cushion system integrates a hydraulic terminal buffering mechanism. This feature absorbs excess force during pressing, minimizing impact, reducing noise, and extending the machine’s service life.

Automatic Lubrication System

A thin-oil automatic lubrication system ensures consistent performance, even under prolonged full-load operation. This lubrication system effectively reduces friction and wear, maintaining machine stability and enhancing longevity.

Lag Latching Cylinder Option

For specialized deep drawing and high-precision forming applications, the air cushion system can be equipped with a lag latching cylinder. This additional component prevents uncontrolled material rise and ensures precise drawing control, making it ideal for intricate manufacturing processes.

Market Demand and Industry Applications

This cutting-edge mechanical press technology is widely adopted across multiple industries, including:

Automotive Industry

Mechanical presses play a crucial role in the automotive sector, where they are used for manufacturing body panels, chassis components, and structural reinforcements. The high precision and efficiency of two-point and four-point single acting presses make them ideal for producing lightweight, high-strength vehicle parts that meet stringent safety and performance standards.

Electronics and Home Appliances

These presses are widely used in the electronics and home appliance industries to shape high-strength materials into complex components. From metal casings for consumer electronics to precision parts for household appliances, the press ensures high-quality production with minimal material wastage.

Aerospace and Defense

In the aerospace and defense industries, the demand for high-strength, lightweight materials is critical. Mechanical presses are utilized to manufacture aircraft components, defense equipment, and other precision-engineered parts that require stringent tolerances and exceptional durability.

Emerging Global Markets

As industrialization expands in developing economies, there is an increasing demand for high-performance stamping equipment. Mechanical presses are being adopted across emerging global markets for applications in infrastructure, renewable energy, and custom fabrication industries.

Why Choose Guangduan for Heavy Stamping Machinery?

Extensive Experience and Expertise

With over 60 years of experience in metal stamping, Guangduan is a leader in the forging and press machine industry. As the largest forging and press machine manufacturer in Southern China, the company has built a strong reputation for delivering high-quality, reliable machinery.

Integrated Development and Innovation

Guangduan manages every aspect of research, development, manufacturing, and servicing of hydraulic, mechanical, and forging press machines. Recognized as a national high-tech enterprise and ranked among the top 50 press machine enterprises in Guangdong Province, the company consistently innovates to meet evolving industry demands.

Skilled Workforce and Cutting-Edge Equipment

With a team of over 800 highly skilled employees and state-of-the-art processing and inspection equipment, Guangduan continuously improves its metal stamping solutions. The company prioritizes customer satisfaction, offering tailored solutions and exceptional after-sales service to meet the unique requirements of each client.

Commitment to Quality and Performance

Guangduan’s mechanical presses are designed with precision engineering, incorporating advanced technology and durable materials to ensure maximum performance, efficiency, and longevity. The company adheres to international quality standards, making it a trusted partner for businesses seeking reliable and high-performing stamping machinery.

Get Reliable and High-Performance Stamping Machinery Today!

Choose Guangduan for durable and precise stamping machines. We have over 60 years of experience. Our machines ensure high efficiency, strong structure, and stable performance. We serve industries like automotive, electronics, and appliances. With 800+ skilled employees and advanced equipment, we provide the best solutions. Contact us now for customized metal stamping solutions. Upgrade your production with Guangduan’s trusted technology. Get a quote today!

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us