Best Heavy Hydraulic Press for Your Needs

Heavy Hydraulic Press is stalwart of modern industrial processes, wielding immense force to shape, mold, and compress materials with precision. These machines are crucial across diverse sectors, from automotive manufacturing to aerospace engineering, where exacting standards and robust performance are non-negotiable.

What is Heavy Hydraulic Press

Heavy Hydraulic Press operates on the principle of hydraulic fluid pressure exerted on a piston to generate force. They typically consist of a sturdy frame, hydraulic system, control unit, and tooling customized for specific tasks. These presses excel in applications requiring high-pressure operations, such as deep drawing, stamping, and forming of metals and composites.

The operation involves the hydraulic pump transmitting fluid into the cylinders, thereby moving the ram or platen to exert force on the material. This force, often measured in thousands of tons, ensures the precise forming and shaping of materials under controlled conditions. Such capability makes Heavy Hydraulic Press indispensable in industries demanding superior force and accuracy.

Meeting Project Needs

Precision and Power: Crucial for High-Pressure Operations

The defining characteristic of Heavy Hydraulic Press lies in their ability to deliver unmatched force and precision. This capability is vital in applications where materials need to be compressed or formed under extreme pressure. Industries such as aerospace and defense rely on this precision to manufacture components that must meet stringent quality and performance standards.

Versatility Across Industries

From automotive part manufacturing to the production of large-scale industrial components, Heavy Hydraulic Press finds versatile applications. In automotive manufacturing, they are used for forming body panels and components, while in aerospace, they shape critical parts like turbine blades and fuselage panels. This adaptability underscores their importance in modern industrial settings.

Customization Options for Unique Requirements

Manufacturers like GUANGDUAN offer customization options to tailor presses to specific project needs. Whether adjusting the press size, capacity, or incorporating specialized features like automated controls or multi-stage pressing, customization ensures that the press aligns perfectly with the project’s requirements. This flexibility enhances operational efficiency and product quality.

Key Considerations When Choosing a Heavy Hydraulic Press

Capacity and Size Matching

Selecting the right press capacity is crucial, as it directly impacts productivity and operational efficiency. Projects requiring higher force and larger workpieces necessitate presses with correspondingly higher tonnage and larger bed sizes. GUANGDUAN’s range of presses caters to varying capacities, ensuring that every project’s needs are met effectively.

Operational Efficiency and Safety Features

Efficiency factors such as cycle time, speed of operation, and energy consumption are critical considerations. Modern presses integrate advanced controls and automation to optimize these parameters, enhancing overall efficiency. Equally important are safety features, including emergency stop mechanisms, interlocks, and safeguarding devices that mitigate risks associated with high-pressure operations.

Maintenance and Support

Reliable service and maintenance support are essential for maximizing press uptime and longevity. Manufacturers like GUANGDUAN provide comprehensive service packages, including routine maintenance, spare parts availability, and technical support. This ensures that the press operates at peak performance throughout its operational life, minimizing downtime and production disruptions.

Case Studies and Real-World Applications

Automotive Industry: Forming and Assembly

In automotive manufacturing, Heavy Hydraulic Press is pivotal for forming metal components such as body panels, chassis parts, and engine components. GUANGDUAN’s presses, equipped with robust hydraulic systems and customized tooling, enable precise shaping of materials to meet stringent design specifications. These presses facilitate efficient production processes, contributing to the quality and durability of vehicles produced by leading automotive brands globally.

Manufacturing: Shaping and Molding Metal Components

Across the manufacturing sector, Heavy Hydraulic Press are instrumental in shaping and molding various metal components used in machinery, equipment, and infrastructure. GUANGDUAN’s extensive range of presses caters to diverse manufacturing needs, from simple stamping operations to complex forging processes requiring high tonnage and precision. These presses enhance productivity and product consistency, supporting industries in meeting market demands effectively.

Steps to Selecting the Best Heavy Hydraulic Press

Assessing Project Needs: Identifying Specific Requirements

Choosing the right heavy hydraulic press begins with a thorough assessment of project requirements. Factors such as required force capacity, operational speed, bed size, and the types of materials to be processed dictate the type of press suitable for the application. GUANGDUAN offers a range of models tailored to different industrial needs, ensuring compatibility with specific project demands.

Researching Options: Comparing Models and Manufacturers

Researching available options involves evaluating different models and manufacturers to find the best match for operational requirements and budget constraints. GUANGDUAN’s extensive experience and reputation for quality and reliability make them a preferred choice among industrial professionals seeking high-performance hydraulic presses. Detailed comparisons of features, specifications, and customer reviews aid in making informed decisions.

Consulting Experts: Seeking Industry Advice

Consulting with industry experts and suppliers, such as GUANGDUAN, provides valuable insights into the latest technological advancements and best practices in heavy hydraulic press selection. Experts can offer recommendations based on specific application needs, ensuring optimal performance and efficiency. GUANGDUAN’s dedicated team of engineers and technicians is equipped to provide comprehensive support and guidance throughout the selection process.

Testing and Validation: Importance of Trials Before Purchase

Before finalizing a heavy hydraulic press purchase, conducting trials and testing its performance under simulated operating conditions is crucial. This validation phase ensures that the press meets expected performance standards and integrates seamlessly into existing production workflows. GUANGDUAN facilitates testing opportunities and provides technical assistance to ensure that customers are confident in their investment and operational outcomes.

Exploring the Excellence of GUANGDUAN: A Leader in Heavy Hydraulic Press Manufacturing

Introduction to GUANGDUAN

GUANGDUAN stands as the largest manufacturer of forging and pressing equipment in South China, recognized for its comprehensive integration of research, development, manufacturing, and service capabilities. As a national high-tech enterprise and a cornerstone of Guangdong Province’s equipment manufacturing sector, GUANGDUAN spearheads major science and technology initiatives. Established under the auspices of Wuzhou Wanshun Forging and Pressing Machine Tool Factory Co., Ltd., the company’s headquarters in Shunde boasts a robust infrastructure, including state-of-the-art production facilities and an extensive team of engineers and technicians.

Innovating Through Research and Development

At the heart of GUANGDUAN’s operations is a commitment to innovation and technological advancement. The company has established prestigious research institutions such as the Postdoctoral Research Station, the Guangdong Forging Equipment Engineering Technology Research and Development Center, and the Guangdong Key Laboratory of Metal Forming Processing and Forging Equipment Technology. These facilities drive continuous improvement and ensure that GUANGDUAN remains at the forefront of forging and pressing equipment innovation globally.

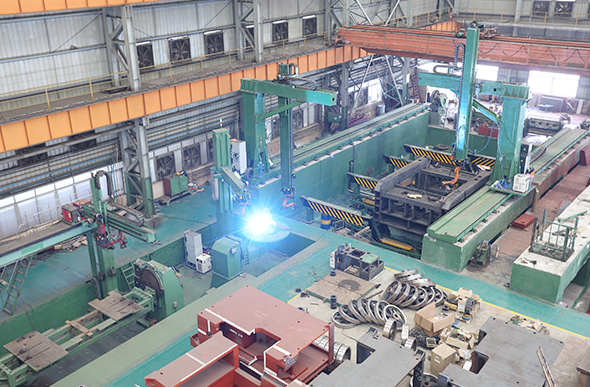

Manufacturing Excellence and Capabilities

GUANGDUAN’s manufacturing prowess is evident in its expansive production capabilities. The company operates over 200 major production equipment units, including CNC machines, floor boring and milling machines, gear grinding machines, and more. With a processing workshop spanning 30,000 square meters and equipped with cranes capable of handling up to 125 tons, GUANGDUAN possesses the infrastructure necessary for large-scale manufacturing of Heavy Hydraulic Press. This robust setup enables the company to deliver products that meet stringent quality standards and exceed customer expectations.

Commitment to Quality and Service

Adhering to a core tenet of “system management, innovation, elaborate manufacturing, quality service,” GUANGDUAN has solidified its position as a premier provider of forging and pressing equipment. The company’s ISO 9001 certifications underscore its commitment to quality management practices, ensuring that every product meets international standards of reliability and performance. Moreover, GUANGDUAN’s quick-response after-sales team ensures prompt support and maintenance services, thereby enhancing customer satisfaction and prolonging the operational lifespan of its equipment.

Technological Leadership and Future Directions

Looking ahead, GUANGDUAN remains steadfast in its pursuit of technological excellence and market leadership. The company focuses on mastering core technologies related to forging and pressing equipment, enhancing its independent research and development capabilities, and driving advancements in the industry. By bridging the gap with global benchmarks and improving international competitiveness, GUANGDUAN aims to establish itself as a leading brand in the global forging and pressing equipment market. This strategic vision underscores its commitment to continuous improvement and innovation, ensuring that customers receive cutting-edge solutions tailored to their evolving needs.

Conclusion

In conclusion, Heavy Hydraulic Press represents the pinnacle of industrial machinery, combining immense force with precise control to meet the demanding requirements of modern manufacturing. Choosing the right press, such as those offered by GUANGDUAN, ensures that projects benefit from superior performance, tailored solutions, and ongoing support. As industries evolve, these presses continue to play a pivotal role in shaping the future of manufacturing, driving innovation and excellence across global industrial landscapes.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us