-

Home / Products / Mechanical Press / Straight Side Double Point Multi Station Press GD2

OUR PRODUCT

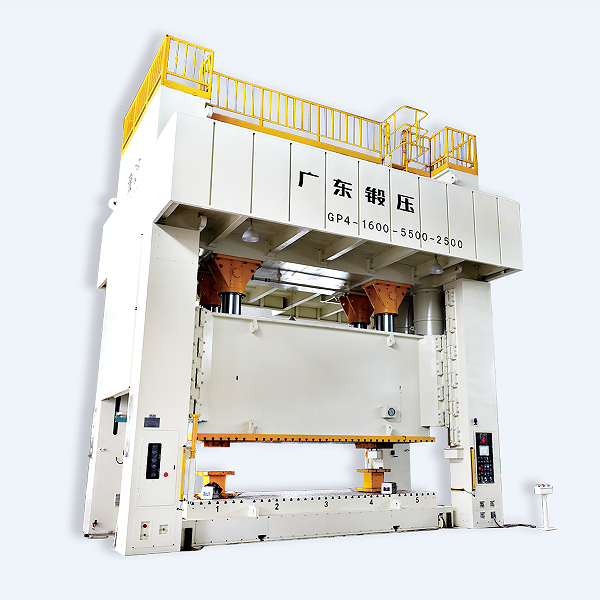

Straight Side Double Point Multi Station Press GD2

Main structural components such as machine body, slide etc., manufactured through welding the superior-quality steel plates, has good rigidity. The machine models with the capacity of above 600t adopt the split machine body and the pull lever pre-tight structure, which makes transportation and installation easy and convenient.

It adopts two-level gear transmission and times of operating strokes of the slide are high.

Interval of the crank and the connecting rod is enlarged, so the machine has the strong unbalance loading resistance capacity, and good precision retentively.

The slide adopts the eight-surface long-guide way guiding, so the side force is low and the precision is high.

It can be provided with the multi-section air cushion specially used for multi-station stamping and the upper knockout cylinder of the slide block.

It is mainly used for the sheet metal stamping of metals, especially suitable for the automation industries such as progressive die and multi-station stamping and so on. In addition, it is provided with the two-dimensional and

three-dimensional servo production line installation interfaces.

|

|

GD2-300 |

GD2-400 |

GD2-500 |

GD2600 |

GD2-800 |

GD2-1000 |

|

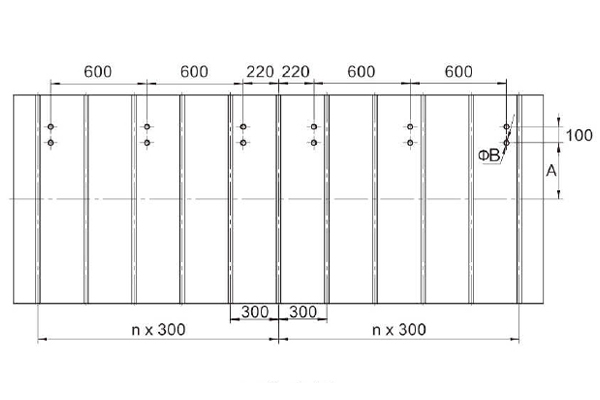

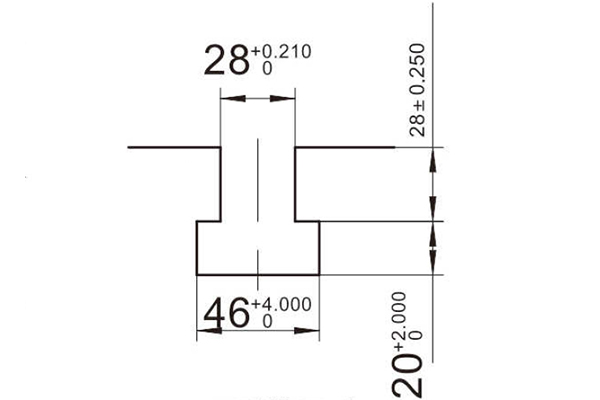

Bolster A |

300 |

350 |

380 |

420 |

450 |

480 |

|

Bolster B |

30 |

30 |

30 |

30 |

303 |

30 |

|

Bolster C |

5 |

5 |

5 |

5 |

6 |

6 |

|

Slide Bolster D |

4 |

4 |

5 |

5 |

6 |

6 |

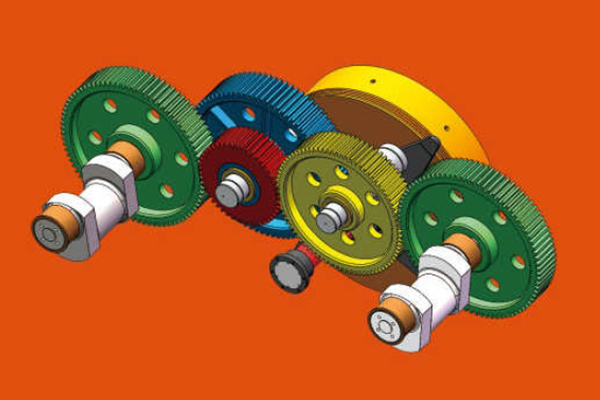

Multi-station Transmission Device

The two-level gear transmission is adopted and a set of idler mechanism is added in the middle enlarge the interval between the pressure spots of the machine, which produces a higher capacity to bear the eccentric load produced by the multi-station and progressive die stampings and can lower the total height of the punching machine and make the structure of the punching machine compact and thereby reducing the space usage of the machine at the same time.

This structural design is suitable for the wide work table surface and multi-station die.

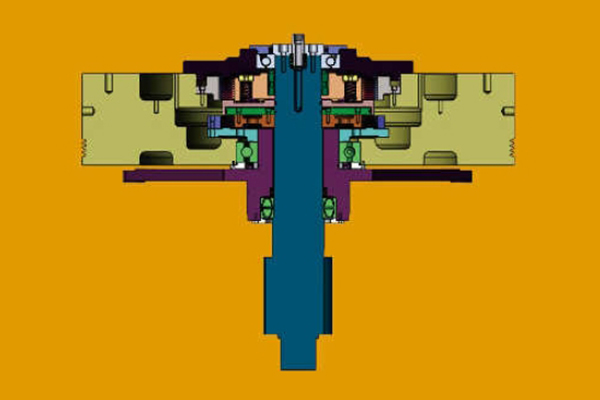

High-torque Wet-type Clutch

● It adopts the oil filled wet-type friction plates and have the large torque, long service life and can be free from being affected by wear.

● The multi-plate low-inertia design makes the machine start and brake sensitively and makes the connection stable.

● It allows many times of interrupted works, so it is suitable for continuous line operation of the operator.

● It is free from pollution and has low noise, so it conforms to environmental requirements.

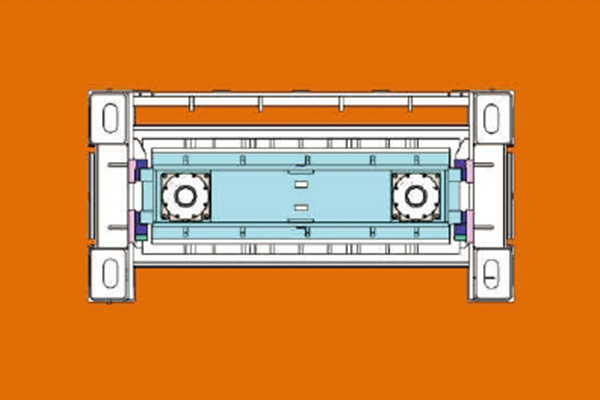

Eight-surface Full-guideway Guiding

The slide adopts the eight-surface full-guideway guiding, so it has the stronger unbalance loading resistance capacity, small side force, high precision and good retentively.

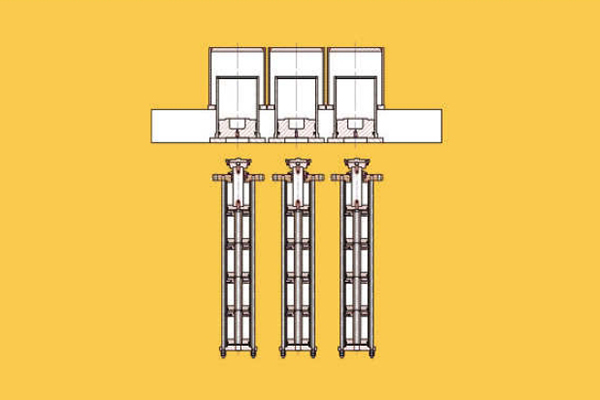

The Upper and Lower Die Cushions Specially Used for The Multi-station Press

● The force of the die cushion is large and the volume of the die cushion is small, which can satisfy different step distances.

● The service life is long and the precision is high.

● The reaction speed of actions is quick and the pressure fluctuation is small.

● Pressure of each die cushion can be adjusted independently.

No information.

GD2 SERIES PROUDUCT PARAMETERS

|

|

Unit |

GD2-300 |

GD2-400 |

GD2-500 |

GD2-600 |

GD2-800 |

GD2-1000 |

|

|

Nominal Capacity |

kN |

3000 |

4000 |

5000 |

6000 |

8000 |

10000 |

|

|

Rating Point A.B.D.C. (Above bottom dead center) |

mm |

7 |

7 |

7 |

7 |

7 |

7 |

|

|

Stroke length |

mm |

280 |

300 |

300 |

320 |

350 |

350 |

|

|

Strokes per minute |

SPM |

18~35 |

18~35 |

18~35 |

18~35 |

15~30 |

15~30 |

|

|

Max. die height |

mm |

600 |

700 |

700 |

800 |

900 |

900 |

|

|

Slide adjustment |

mm |

120 |

140 |

140 |

200 |

200 |

200 |

|

|

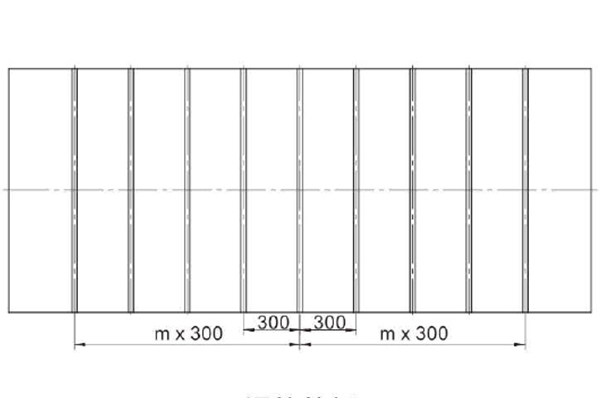

Bolster area |

LR |

mm |

3300 |

3300 |

3500 |

3600 |

3800 |

4000 |

|

FB |

mm |

1200 |

1300 |

1400 |

1500 |

1600 |

1700 |

|

|

Slide bolster area |

LR |

mm |

3100 |

3100 |

3300 |

3400 |

3600 |

3800 |

|

FB |

mm |

1100 |

1200 |

1300 |

1400 |

1500 |

1600 |

|

|

Side opening |

UD |

mm |

630 |

670 |

670 |

720 |

850 |

850 |

|

FB |

mm |

1100 |

1200 |

1300 |

1400 |

1550 |

1650 |

|

|

Main motor |

kW |

37 |

55 |

55 |

75 |

90 |

110 |

|

|

Motor for slide adjustment |

kW |

4 |

4 |

4 |

5.5 |

5.5 |

7.5 |

|

|

Overall dimension |

LR |

mm |

4300 |

4350 |

4530 |

4630 |

5200 |

5400 |

|

FB |

mm |

3200 |

3460 |

3750 |

3900 |

4300 |

4500 |

|

|

H |

mm |

5200 |

5555 |

5776 |

6170 |

7500 |

7800 |

|

|

Total weight (approximately) |

ton |

65 |

70 |

82 |

92 |

120 |

145 |

|

|

Air pressure required |

MPa |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

|

Remarks: please forgive there is not a further notice if individual parameters are modified.

GD2 SERIES CONFIGURATION

Standard Functional Configuration

● T-shape two-hand button operating board (movable)

● Touching type supervising controller

● Hydraulic overload protective device

● Over-run protective device

● Accumulative 8-bit counter

● Single 4-bit counter

● Preset 4-bit counter

● Motor-driven slide block adjustment device

● Automatic lubricating device

● Misfeed detecting interface

● Electronic cam control

● Lighting lamp for die

● Frequency control of motor speed

● LCD frequency converter operating panel

● Digital die height indicator (Unit 0.1mm)

● Wet-type clutch

● Slide block and die balancer

● Electronic type crank angle indicator

● Inversion set of the main motor

● Operating instruction and precision inspection table

● Coupling for air blowing

● Coupling for air source

● Double solenoid valve

Selective Functional Configuration

● Air cushion

● Ejector device in the upper of the slide block

● Photo-electric protection

● Shockproof sizing block

● Quick die change device

● Flywheel brake equipment

● Safety cock

● Load monitor

● Die safety detector

● Foundation bolt

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us