-

Home / Products / Mechanical Press / Open Back Power Press GPA Series

OUR PRODUCT

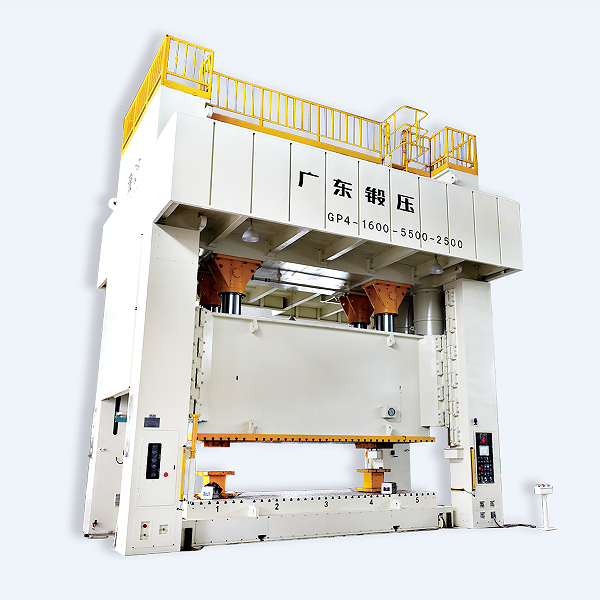

Open Back Power Press GPA Series

The machine adopts press frame design of high rigidity and steel plate welding of high quality.

The transmission centre is the same of the machine centre to ensure the accuracy and stability.

Die height adjustment accuracy reaches up to 0.1m for safe, convenient and reliable adjustment.

Gear pair and sliding pair are smooth, high-precision and of low noise after quenching and precision grinding.

GPA SERIES OPEN-BACK POWER PRESSES

The machine adopts high rigidity press frame design and high quality steel plate welding.

The transmission centre is the same of the machine centre to ensure the accuracy and stability.

Die height adjustment accuracy reaches up to 0.1m for safe, convenient and reliable adjustment.

Gear pair and sliding pair are smooth, high-precision and of low noise after quenching and precision grinding.

The machine adopts symmetrical balancer design to make sure smooth operation.

Dry clutch and dual solenoid valve with famous brands are applied so as to increase safety performance and ensure low noise.

Hydraulic overload protective device is equipped for high sensitivity and safety during operation.

With PLC control, the machine can achieve automatic production with robot as well as feeding system.

No information.

GPA SERIES PRODUCT PARAMETER

| Unit | GPA-25 | GPA-45 | GPA-60 | GPA-80 | GPA-110 | GPA-160 | GPA-200 | GPA-260 | |||||||||||||||

| Model | V | H | V | H | V | H | V | H | V | H | V | H | V | H | V | H | |||||||

| Nominal Capacity | kN | 250 | 450 | 600 | 800 | 1100 | 1600 | 2000 | 2600 | ||||||||||||||

|

Rating Point A.B.D.C. (Above bottom dead center) |

mm | 3.2 | 1.6 | 3.2 | 1.6 | 4 | 2 | 4 | 2 | 6 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | ||||||

| Stroke Length | mm | 60 | 30 | 80 | 50 | 120 | 60 | 150 | 70 | 180 | 80 | 200 | 90 | 200 | 100 | 250 | 150 | ||||||

| Stroke Per Minutes | SPM | 60-140 | 130-200 | 40-100 | 110-150 | 35-90 | 80-120 | 35-80 | 80-120 | 30-60 | 60-90 | 20-50 | 40-70 | 20-50 | 50-70 | 20-40 | 40-50 | ||||||

| Max. die Height | mm | 200 | 215 | 250 | 265 | 310 | 340 | 340 | 380 | 360 | 410 | 460 | 510 | 460 | 510 | 500 | 550 | ||||||

| Slide adjustment | mm | 50 | 60 | 75 | 80 | 80 | 100 | 110 | 120 | ||||||||||||||

| Depth of throat | mm | 155 | 225 | 255 | 280 | 305 | 405 | 415 | 430 | ||||||||||||||

| Bolster Area | LR | mm | 680 | 850 | 900 | 1000 | 1150 | 1250 | 1400 | 1500 | |||||||||||||

| FB | mm | 300 | 440 | 500 | 550 | 6000 | 800 | 820 | 840 | ||||||||||||||

| THK | mm | 70 | 80 | 80 | 90 | 110 | 140 | 160 | 180 | ||||||||||||||

| Slide Area | LR | mm | 300 | 400 | 500 | 560 | 650 | 700 | 850 | 950 | |||||||||||||

| FB | mm | 220 | 300 | 360 | 420 | 470 | 550 | 630 | 700 | ||||||||||||||

| Die Shank Hole (dia) | mm | Ø38 | Ø38 | Ø50 | Ø50 | Ø50 | Ø65 | Ø65 | Ø65 | ||||||||||||||

| Main motor | kW | 3.7 | 5.5 | 5.5 | 7.5 | 11 | 15 | 15 | 22 | ||||||||||||||

| Bolster to ground | mm | 795 | 790 | 795 | 830 | 830 | 900 | 995 | 1030 | ||||||||||||||

| Distance between columns | mm | 444 | 502 | 526 | 534 | 616 | 660 | 800 | 900 | ||||||||||||||

| Over Dimension | LR | mm | 940 | 950 | 1000 | 1100 | 1300 | 1400 | 1690 | 1850 | |||||||||||||

| FB | mm | 1350 | 1600 | 1600 | 1800 | 1900 | 2300 | 2615 | 2780 | ||||||||||||||

| H | mm | 2230 | 2500 | 2850 | 2900 | 3200 | 3800 | 4075 | 4470 | ||||||||||||||

| Weight | kg | 2030 | 3300 | 4300 | 6500 | 9500 | 16000 | 23000 | 32000 | ||||||||||||||

| Air Pressure Used | MPa | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | ||||||||||||||

| Capacity | kN | — | 23 | 36 | 36 | 63 | 100 | 140 | 140 | ||||||||||||||

| Stroke length | mm | — | 50 | 70 | 70 | 80 | 80 | 100 | 100 | ||||||||||||||

GPA SERIES DIMESION OF THE BOLSTER AND SLIDE BOTTOM PLATE

Bolster Area

| Model | GPA-25 | GPA-45 | GPA-60 | GPA-80 | GPA-110 | GPA-160 | GPA-200 | GPA-260 |

| L1 | 680 | 850 | 900 | 1000 | 1150 | 1250 | 1400 | 1500 |

| L2 | 300 | 440 | 500 | 550 | 600 | 800 | 820 | 840 |

| L3 | 180 | 240 | 300 | 300 | 320 | 440 | 560 | 580 |

| L4 | 120 | 150 | 160 | 180 | 200 | 220 | 240 | 260 |

| L5 | 240 | 300 | 320 | 360 | 400 | 440 | 480 | 520 |

Unit: mm

Slide Area

| Model | GPA-25 | GPA-45 | GPA-60 | GPA-80 | GPA-110 | GPA-160 | GPA-200 | GPA-260 |

| L1 | 300 | 400 | 500 | 560 | 650 | 700 | 750 | 950 |

| L2 | — | — | 220 | 300 | 300 | 300 | 420 | 420 |

| L3 | 150 | 180 | 220 | 220 | 220 | 175 | 200 | 200 |

| L4 | 80 | 120 | 160 | 180 | 220 | 220 | 300 | 300 |

| L5 | 245 | 300 | 360 | 420 | 470 | 550 | 630 | 700 |

| D | 38 | 38 | 50 | 50 | 50 | 65 | 65 | 65 |

Unit: mm

T-Slot Dims

| Model | GPA-25 | GPA-45 | GPA-60 | GPA-80 | GPA-110 | GPA-160 | GPA-200 | GPA-260 |

| L1 | 18 | 18 | 22 | 22 | 22 | 22 | 22 | 22 |

| L2 | 30 | 30 | 37 | 37 | 37 | 37 | 37 | 37 |

| L3 | 18 | 18 | 24 | 24 | 24 | 24 | 24 | 24 |

| L4 | 12 | 12 | 16 | 16 | 16 | 16 | 16 | 16 |

Unit: mm

GPA SERIES CONFIGURATION

Standard Configuration

Dry-type clutch

Hydraulic overload protective device

(GPA 80-260)Motor-driven slide block adjustment device (GPA 80-260)

(GPA 45-60)Manual slider adjustment device (GPA 45-60)

Pneumatic grease lubrication device

Slide block and die balancing device

Electronic cam controller

Digital die height indicator (Unit 1mm)

Counter

Frequency control of motor speed

Over-run protective device

Double solenoid valve

Programmable controller

Stationary two-hand control button station

Coupling for air blowing

Coupling for air source

Misfeed detecting circuit

Inversion set of the main motor

Operating instruction and precision inspection table

Shockproof sizing block

Optional Configuration

Sider upper discharge device

Automatic feeding axis

Pneumatic die pad device

Gas liquid mold pad device

220 single phase of the convenience receptacle

Lighting lamp for die

Foot switch

Movable to hand contra button station

Preset counter

Safety net

Foundation on bot

Quick die change device

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us