-

Home / Products / Mechanical Press / Mechanical Punch Press STPP Series

OUR PRODUCT

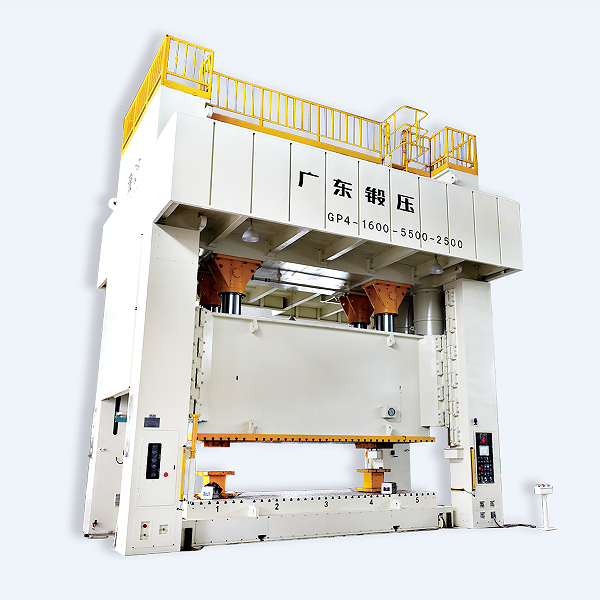

Mechanical Punch Press STPP Series

The machine body is manufactured by welding the steel plates with good rigidity. The double crankshafts are designed in the reverse way, which makes the motion of the machine balanced and counteracts the side force of the linkage side block.

The slider is guided by eight-sided full guide rails, which has a stronger anti-unbalance bearing capacity, small lateral force, high precision and good retention.

What is Mechanical Punch Press?

A mechanical punch press is one type of punch press that is designed for cutting the desired shapes through the die sets. The primary mission of mechanical punch presses is to cut out certain shapes on sheet metal with the die just like general punch press machines and is critical for producing cuts with high precision.

Features

- The hydraulic overload protective device is installed inside the slide block, so it works rapidly, sensitively, and reliably.

- The clutch adopts a high-torque wet clutch, which has large torque, long service life and is not affected by wear and tear. At the same time, it has no pollution, low noise, and is sensitive to start and brake.

- This mechanical punch press machine adopts the PLC control method, and it can be provided with the automatic production line and uncoiling leveling device to achieve automated stamping production of a single machine or many machines.

No information.

Remarks: Specifications are subject to change without notice.

|

|

Unit |

STPP-160 |

STPP-250 |

STPP-300 |

STPP-350 |

STPP-400 |

STPP-400K |

STPP-500 |

STPP-600 |

|

|

Nominal Capacity |

kN |

1600 |

2500 |

3000 |

3500 |

4000 |

4000 |

5000 |

6000 |

|

|

Rating Point A.B.D.C. (Above bottom dead center) |

mm |

6 |

7 |

7 |

7 |

7 |

7 |

7 |

7 |

|

| Stroke length |

mm |

200 |

250 |

250 |

280 |

300 |

300 |

320 |

320 |

|

| Strokes per minute |

SPM |

30-55 |

25-45 |

20-35 |

20-35 |

20-35 |

20-35 |

15-30 |

15-30 |

|

| Max. die height |

mm |

450 |

500 |

550 |

600 |

600 |

700 |

800 |

800 |

|

| Slide adjustment |

mm |

100 |

110 |

120 |

120 |

140 |

140 |

140 |

200 |

|

| Side Window opening | FB |

mm |

760 |

920 |

1200 |

1200 |

1200 |

1200 |

1200 |

1200 |

| UD |

mm |

480 |

480 |

610 |

620 |

610 |

660 |

680 |

680 |

|

| Bolster area | FB |

mm |

800 |

840 |

1000 |

1100 |

1100 |

1200 |

1300 |

1300 |

| LR |

mm |

1860 |

2200 |

2500 |

2700 |

2700 |

3000 |

3200 |

3400 |

|

| Slide area | FB |

mm |

700 |

750 |

900 |

1000 |

1000 |

1100 |

1200 |

1200 |

| LR |

mm |

1800 |

1900 |

2200 |

2400 |

2400 |

2800 |

3000 |

3200 |

|

| Distance between columns |

mm |

2120 |

2300 |

2600 |

2810 |

2800 |

3100 |

3400 |

3600 |

|

| Main motor |

kW |

18.5 |

22 |

30 |

37 |

37 |

45 |

55 |

55 |

|

| Bolster to ground |

mm |

1.5 |

3 |

3 |

4 |

4 |

4 |

4 |

4 |

|

|

mm |

1000 |

1000 |

1140 |

1240 |

1250 |

1330 |

1340 |

1400 |

||

| Overall dimension | FB |

mm |

2720 |

2600 |

3020 |

3140 |

3140 |

3140 |

3400 |

3630 |

| LR |

mm |

2880 |

3140 |

3490 |

3700 |

3780 |

4130 |

4430 |

4620 |

|

| H |

mm |

3800 |

4315 |

4820 |

5130 |

5300 |

5370 |

5780 |

6090 |

|

| Weight (net) | kg |

27000 |

31000 |

41000 |

52000 |

56000 |

65000 |

79000 |

92000 |

|

| Cushion(Optional) | Capacity | kN |

2×100 |

2×120 |

2×120 |

2×120 |

2×120 |

2×140 |

2×140 |

2×140 |

| Stroke length | mm |

100 |

100 |

100 |

110 |

140 |

140 |

140 |

140 |

|

| Air pressure used | MPa |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

|

|

|

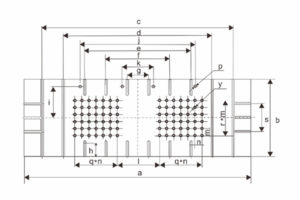

|

Model |

STPP-160 |

STPP-250 |

STPP-300 |

STPP-350 |

STPP-400 |

STPP-400K |

STPP-500 |

STPP-600 |

|

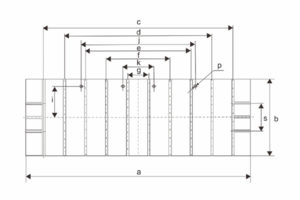

a |

1860 |

2200 |

2500 |

2700 |

2700 |

3000 |

3200 |

3400 |

|

b |

800 |

840 |

1000 |

1100 |

1100 |

1200 |

1300 |

1300 |

|

c |

1540 |

1750 |

2100 |

2100 |

2100 |

2700 |

2700 |

2700 |

|

s |

400 |

400 |

400 |

500 |

500 |

600 |

600 |

600 |

|

d |

1250 |

1250 |

1500 |

1500 |

1500 |

2100 |

2100 |

2100 |

|

e |

— |

— |

— |

— |

— |

1500 |

1500 |

1500 |

|

f |

750 |

750 |

900 |

900 |

900 |

900 |

900 |

900 |

|

g |

250 |

250 |

300 |

300 |

300 |

300 |

300 |

300 |

|

h |

140 |

190 |

220 |

220 |

220 |

250 |

280 |

320 |

|

i |

300 |

320 |

400 |

450 |

450 |

500 |

550 |

550 |

|

j |

1440 |

1440 |

1630 |

1630 |

1630 |

1630 |

1630 |

1630 |

|

k |

440 |

440 |

440 |

440 |

440 |

440 |

440 |

440 |

|

l |

300 |

460 |

460 |

460 |

460 |

600 |

600 |

600 |

|

m |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

n |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

p |

4-Φ30 |

4-Φ30 |

4-Φ30 |

4-Φ30 |

4-Φ30 |

4-Φ30 |

4-Φ30 |

4-Φ30 |

|

q |

4 |

4 |

4 |

4 |

4 |

6 |

6 |

6 |

|

r |

3 |

3 |

4 |

4 |

4 |

5 |

5 |

5 |

|

y |

40-Φ32 |

40-Φ32 |

50-Φ32 |

50-Φ32 |

50-Φ32 |

80-Φ32 |

84-Φ32 |

84-Φ32 |

Remarks: Specifications are subject to change without notice.

Remarks: Specifications are subject to change without notice.

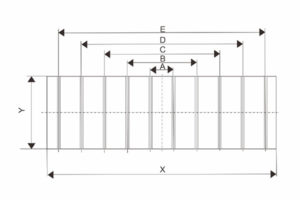

|

Model |

STPP-160 |

STPP-250 |

STPP-300 |

STPP-350 |

STPP-400 |

STPP-400K |

STPP-500 |

STPP-600 |

|

X |

1800 |

1900 |

2200 |

2400 |

2400 |

2800 |

3000 |

3200 |

|

Y |

700 |

750 |

900 |

1000 |

1000 |

1100 |

1200 |

1200 |

|

A |

250 |

250 |

300 |

300 |

300 |

300 |

300 |

300 |

|

B |

750 |

750 |

900 |

900 |

900 |

900 |

900 |

900 |

|

C |

1250 |

1250 |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

|

D |

— |

— |

— |

2100 |

2100 |

2100 |

2100 |

2100 |

|

E |

— |

— |

— |

— |

— |

2700 |

2700 |

2700 |

Remarks: Specifications are subject to change without notice.

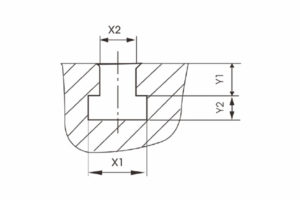

|

Model |

STPP-160 |

STPP-250 |

STPP-300 |

STPP-350 |

STPP-400 |

STPP-400K |

STPP-500 |

STPP-600 |

|

x1 |

46 |

46 |

46 |

46 |

46 |

46 |

46 |

46 |

|

x2 |

28 |

28 |

28 |

28 |

28 |

28 |

28 |

28 |

|

y1 |

28 |

28 |

28 |

28 |

28 |

28 |

28 |

28 |

|

y2 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

Standard Configuration

T-shape two-hand button operating board (movable)

Touching type supervising controller

Hydraulic overload protective device

Over-run protective device

Accumulative 8-bit counter

Single 4-bit counter

Preset 4-bit counter

Motor-driven slide block adjustment device

Automatic lubricating device

Misfeed detecting interface

Electronic cam controller

Photo-electric protection

Frequency control of motor speed

LCD frequency converter operating panel

Digital die height indicator (Unit 0.1mm)

Wet-type clutch

Slide block and die balancer

Electronic type crank angle indicator

Inversion set of the main motor

Operating instruction and precision inspection table

Coupling for air blowing

Coupling for air source

Double solenoid valve

Shockproof sizing block

Optional Configuration

Air cushion

Ejector devise in the upper of the slide block

Quick die change device

Flywheel brake equipment

Safety cock

Load monitor

Die safety detector

Foundation bolt

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us