High-Performance Straight Side Double Point Multi-Station Stamping Press

How Are Large Metal Parts Made with High Precision?

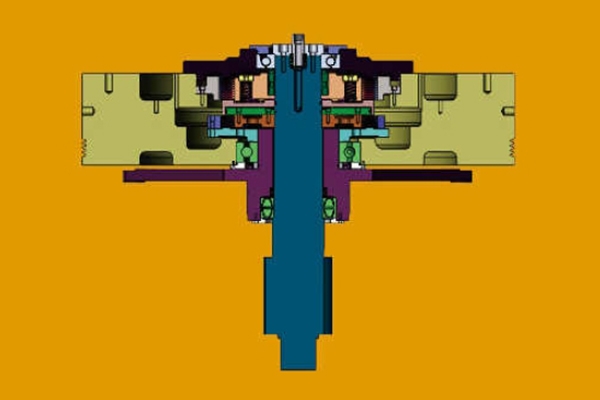

The Guangduan Straight Side Double Point Multi-Station Stamping Press GD2 is a powerful and advanced machine widely used across various industries to manufacture large metal parts with high precision.

The machine’s key components, including the body and slide, are constructed by welding robust steel plates, ensuring a rigid and durable structure. In models exceeding 600 tons of capacity, a split body and pull lever pre-tight structure are incorporated, simplifying transportation and installation.

This stamping press plays a crucial role in industries such as automotive, aerospace, electronics, and metal fabrication. Many companies depend on it to produce high-quality metal parts efficiently and at scale.

Key Features and Capabilities

High-Speed Operation

This advanced stamping machine is designed for high-speed production, utilizing a two-level gear transmission system. This innovative design allows the slide to move at an accelerated pace, completing more strokes per unit of time. As a result, manufacturers benefit from increased efficiency, reduced cycle times, and improved overall productivity. By integrating high-speed mechanics with precision engineering, this machine ensures a seamless and rapid stamping process, making it an indispensable asset for industrial operations.

Robust and Precise Performance

Engineered for durability and strength, this machine features an optimized crank and connecting rod placement, increasing the space between them. This structural enhancement significantly improves the machine’s ability to handle unbalanced loads while maintaining precision. Even under heavy operational demands, this machine retains its accuracy over extended periods, reducing wear and tear. Manufacturers can rely on its robust design for consistent and high-quality output, ensuring longevity and reliability in high-volume production settings.

Stable and Accurate Movement

The slide mechanism is designed with an eight-surface long-guide way, minimizing side forces and ensuring precision during operation. This setup enhances stability and control, even when handling heavy loads. The design significantly reduces deflection and misalignment, leading to consistently accurate stamping results. The improved guidance system ensures that every movement is smooth and controlled, enhancing the machine’s overall efficiency and reliability.

Multi-Station Stamping Support

One of the standout features of this stamping machine is its multi-station stamping capability. Equipped with a multi-section air cushion, it is specifically designed to accommodate multi-station stamping operations. Additionally, the slide block includes an upper knockout cylinder, further optimizing the stamping process. This feature enhances the machine’s adaptability to complex production requirements, making it suitable for a broad range of industrial applications.

Ideal for Metal Stamping

This machine is a premier choice for sheet metal stamping, widely used in automation-driven industries. It is particularly effective in progressive die and multi-station stamping applications. The machine supports two-dimensional and three-dimensional servo production line installation interfaces, ensuring seamless integration with modern manufacturing systems. Its adaptability makes it suitable for a variety of production needs, allowing manufacturers to scale their operations efficiently.

Benefits for Manufacturers

Increased Productivity

With its high-speed operational capability, this machine significantly reduces cycle times, allowing manufacturers to produce more parts in a shorter timeframe. This efficiency boost helps businesses meet high production demands while maintaining quality standards. The machine’s ability to handle multiple strokes quickly ensures that manufacturing output remains consistently high, meeting the rigorous demands of competitive industrial sectors.

Enhanced Part Quality

Precision is a crucial aspect of any stamping operation, and this machine ensures consistent accuracy. By reducing errors and maintaining uniformity in stamping processes, it minimizes material wastage and decreases the need for rework. This precision not only enhances part quality but also leads to cost savings by maximizing material utilization and reducing operational inefficiencies.

Energy Efficiency

Equipped with an advanced power management system, this machine optimizes energy consumption without compromising performance. By utilizing energy-efficient technologies, manufacturers can significantly reduce electricity costs while maintaining high production rates. This eco-friendly approach not only lowers operational expenses but also aligns with sustainability initiatives, making it an ideal choice for environmentally-conscious businesses.

Versatility Across Applications

The flexibility of this stamping machine makes it a valuable asset across multiple industrial applications. It supports various stamping processes, including progressive die, transfer die, and tandem press operations. This adaptability allows manufacturers to cater to diverse production needs, making the machine a cost-effective and multi-functional investment.

Industry Applications

Automotive Industry

In the automotive sector, precision and strength are paramount. This machine plays a crucial role in manufacturing essential components such as chassis parts, brackets, and body panels. Given the stringent quality standards in the automotive industry, this stamping machine’s reliability and precision make it an invaluable tool for high-volume production.

Aerospace Industry

Aerospace manufacturing demands the highest levels of precision and durability. This stamping machine is instrumental in producing metal components for aircraft assembly, ensuring compliance with industry regulations and quality standards. The ability to manufacture complex parts with exceptional accuracy makes it a preferred choice in aerospace production lines.

Electronics Industry

The electronics industry requires the stamping of small, intricate components with absolute precision. This machine enables high-speed stamping of electrical enclosures, connectors, and circuit board components. The accuracy and consistency of the machine ensure the production of high-quality electronic parts, meeting the increasing demand for miniaturized and sophisticated electronic devices.

Heavy Machinery Industry

For manufacturers in the heavy machinery sector, the need for durable and strong structural components is critical. This machine facilitates the production of robust parts capable of withstanding extreme operational conditions. Its ability to stamp thick and heavy metal sheets makes it an essential asset for industries that require high-strength components.

Expert and Industry Insights

Industry Leader Opinions

Manufacturing experts see the Guangduan Straight Side Double Point Multi-Station Stamping Press as a game-changer. They say it boosts production speed, improves part quality, and lowers energy consumption. Many companies have already adopted it to make their processes more efficient.

User Testimonials

John Li, Production Manager at XTech Automotive, says, “Since using this machine, our production speed has increased by 30%, and part quality has never been better.”

Emily Chen, Operations Head at Precision Metals, shares, “We used to waste a lot of material due to errors, but this press ensures precise stamping every time, saving us both time and costs.”

Michael Zhang, CEO of AeroFab, adds, “Its flexibility allows us to handle different stamping tasks with ease. This machine has truly improved our workflow.”

Upgrade Your Production with the Guangduan Stamping Press!

This machine is fast, strong, and precise. It helps you make high-quality parts with less waste. It saves energy and lowers costs. Many industries use it for metal stamping. It works well for automotive, aerospace, electronics, and heavy machinery.

Manufacturers trust this machine. It improves speed and quality. It handles different stamping tasks easily. Many companies have already upgraded.

Boost your production today! Get the Guangduan Straight Side Double Point Multi-Station Stamping Press now.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us