Unleashing the Efficiency of Two-Point/Four-Point Single Acting Press Machines in Industrial Manufacturing

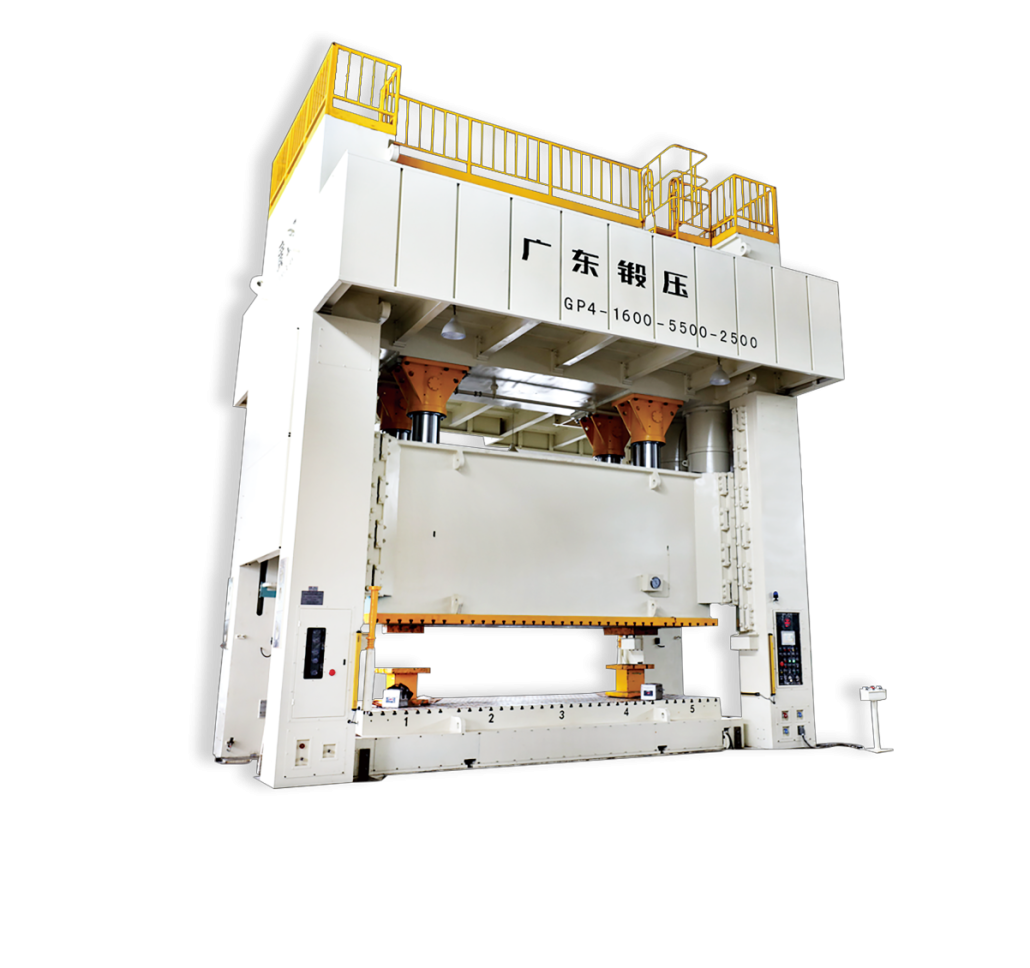

There is a growing demand for high-efficiency machines in industrial manufacturing, and one key solution to meet this demand is the two-point/four-point single-acting press machines. These machines play a crucial role in driving this shift. Guangduan’s press machine, for example, features a strong, durable body constructed by welding steel plates together, followed by high-temperature annealing. This process enhances the machine’s rigidity and stability. Additionally, the machine comes with a self-moving work table and a die clamping system, which significantly improves die change efficiency. Could this be the right solution for your needs?

How Two-Point/Four-Point Systems Work

Industrial manufacturing is evolving rapidly with the need for more efficient and reliable machinery. Among the many advancements, the two-point and four-point press systems stand out as a key solution to improving production efficiency and quality. Understanding the mechanics behind these systems is essential for manufacturers looking to optimize their operations.

Mechanics Behind Two-Point and Four-Point Press Designs

At the core of two-point and four-point press systems is the way force is applied to the workpiece. In a two-point system, force is applied at two specific points on the press machine. This means that the pressure is concentrated at these two points, but the distribution is relatively less balanced compared to the four-point system. On the other hand, the four-point press uses four points of contact, allowing for a more even distribution of pressure across the workpiece.

The distribution of force is critical for several reasons:

Even Pressure Distribution: Both systems ensure that the workpiece is pressed uniformly, which is essential for high-quality production, especially in precision industries.

Prevention of Uneven Wear: By applying force at multiple points, wear and tear on the machine components are spread more evenly, resulting in longer machine life and reduced maintenance costs.

The choice between a two-point and four-point press often depends on the complexity and precision required for the job. The four-point system generally offers superior stability and accuracy, especially for high-precision applications.

Key Differences Between Single-Acting and Other Press Systems

The fundamental difference between single-acting press systems and multi-point presses like the two-point or four-point systems lies in the number of force application points.

Single-Acting Press: As the name suggests, a single-acting press applies force at only one point. This makes the system simpler and often more affordable, but it can lead to uneven pressure distribution, which may result in issues like poor product quality or machine wear over time.

Multi-Point Press (Two-Point/Four-Point): These presses distribute force at multiple points, which helps to balance the load across the machine. This results in more even pressure on the workpiece, better product quality, and reduced strain on the machine. The downside is that these systems are typically more complex and expensive than single-acting presses. However, the advantages in efficiency, machine longevity, and product consistency often outweigh the initial cost.

In essence, while single-acting presses are simpler and often cost-effective, multi-point presses provide superior efficiency and longevity, making them a better choice for high-volume and high-precision manufacturing.

The Main Transmission Structure

The transmission structure in press machines is a key component responsible for efficiently directing force across various parts of the machine. In most high-efficiency press machines, this transmission structure involves a series of five shafts, which guide the force in different directions. The gears are strategically arranged symmetrically, ensuring smooth operation and minimizing mechanical strain.

Additionally, the press is equipped with a guide pillar and guide sleeve, which provide added stability and prevent misalignment during operation. These components work together to ensure that the machine runs efficiently and with high precision. When the machine is operating smoothly, the production process becomes more reliable, reducing the likelihood of defects and the need for adjustments during the run.

Air Cushion for High Tonnage

In modern press systems, the use of an air cushion adds another layer of efficiency, especially in machines that require high tonnage. This air cushion uses pure gas to enhance the pressing force, making it capable of handling more demanding tasks.

The air cushion assists in both blank pressing and ejection. In blank pressing, it ensures that the material is uniformly compressed across its surface. In the ejection process, it helps push the finished product out of the die without causing damage. The cushion also helps with flexibility, allowing the press to handle a wider range of production demands, from delicate materials to tougher, high-strength workpieces.

Enhanced Precision and Speed: Boosting Production Quality

The need for high-quality production output is at the heart of industrial manufacturing. Advances in press technology, particularly in the design of machine components, have contributed to improvements in both precision and speed.

Machine Body Construction for Stability

The machine body is one of the most important structural elements of a press. Guangduan’s press machine, for example, is built by welding steel plates together to form a sturdy frame. Once assembled, the machine undergoes a high-temperature annealing process. This process is designed to relieve internal stresses in the steel, resulting in a more rigid and stable structure.

This stability is essential for precision work. A rigid frame ensures that the press does not flex or shift during operation, which can lead to inconsistent product quality. This design helps the machine perform with high precision, even under heavy loads, making it ideal for applications requiring tight tolerances.

Self-Moving Work Table and Die Clamping System

Speed and efficiency in changing dies are critical for optimizing production time. Many modern presses, including those with two-point or four-point systems, feature a self-moving work table. This innovation allows the workpiece to be easily positioned and adjusted without manual intervention.

Additionally, the machine is equipped with a die clamping system that significantly improves die change efficiency. The clamping system allows for quick and secure die changes, reducing downtime and enabling faster transitions between different production runs. This feature is particularly valuable in high-volume manufacturing environments, where time and efficiency are of the essence.

Eight-Surface Long-Guideway for Stability

To enhance the precision of the press, the machine’s slide is supported by an eight-surface long-guideway. This design provides more contact points between the slide and guideway, which helps maintain high stability and alignment during operation.

By ensuring that the machine components remain aligned, this guiding system minimizes mechanical errors, which is crucial for consistent product quality. As a result, manufacturers can produce items that meet strict tolerances, boosting the overall quality of production.

Cost-Effectiveness: Reducing Operational Expenses

In addition to improving precision and efficiency, modern press systems are designed to reduce operational costs, which is an important factor for manufacturers looking to stay competitive in the marketplace.

Lowering Manufacturing Costs by Minimizing Waste and Downtime

Modern press machines are equipped with PLC control systems, which automate various aspects of the machine’s operation. This includes adjusting parameters like air pressure, die set height, and air cushion stroke. The result is a smoother, more efficient operation with less need for manual intervention.

By reducing the amount of waste material produced and cutting down on downtime between runs, manufacturers can significantly lower their operational costs. The automation of certain processes also improves production consistency, ensuring that each item meets quality standards.

Potential Savings on Labor, Energy, and Maintenance

High-efficiency presses are equipped with features that reduce the need for constant manual oversight and maintenance. For instance, the automatic circulating lubrication system ensures that components are well-lubricated, reducing wear and extending the machine’s lifespan.

Moreover, automatic monitoring systems track critical parameters such as pressure, temperature, oil levels, and flow rates, which ensures the machine runs at peak efficiency. The inclusion of automatic feeding and leveling devices allows the press to function autonomously during stamping operations, further reducing labor costs and improving energy efficiency.

Boost Efficiency with Two-Point/Four-Point Press Machines

The two-point and four-point press systems are designed to distribute force evenly across the workpiece, ensuring balanced pressure throughout the process. This results in improved product quality and minimizes wear on the machine. Constructed from welded steel plates and undergoing high-temperature annealing, these presses offer exceptional stability and precision, even in high-demand applications. Upgrade to a two-point or four-point press to enhance production speed, improve product consistency, and save on long-term maintenance costs.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us