Are Hydraulic Presses for Sale a Cost-Effective Solution for Your Business?

Metal Forming stands as the backbone of various industries, from automotive to aerospace, catering to the demand for intricate metal components. In this blog, we delve into the dynamic landscape of the Metal Forming sector, shedding light on market trends, challenges, and the pivotal role Hydraulic Presses for Sale plays in revolutionizing manufacturing processes.

Understanding Metal Forming Industry Dynamics

1.1 Current Market Trends: Adaptation and Innovation

In the ever-evolving Metal Forming landscape, manufacturers are witnessing a paradigm shift driven by technological advancements and changing consumer demands. From the adoption of Industry 4.0 principles to the integration of automation and robotics, the industry is embracing transformative trends to enhance productivity and stay competitive.

1.2 Growth Projections and Emerging Technologies: Paving the Path Forward

With burgeoning demand for lightweight materials and complex geometries, the Metal Forming industry is poised for substantial growth in the coming years. Additive manufacturing, augmented reality, and advanced simulation techniques are among the emerging technologies reshaping the manufacturing landscape, offering unprecedented opportunities for innovation and efficiency gains.

Evolving Needs and Challenges in Metal Forming

2.1 Production Efficiency and Quality Control: Striving for Perfection

Metal Forming manufacturers face relentless pressure to streamline production processes while ensuring uncompromised quality. Balancing speed and precision remains a perpetual challenge, necessitating continuous optimization of manufacturing workflows and stringent quality control measures to meet customer expectations.

2.2 Material Handling and Process Complexity: Navigating the Maze

Navigating the intricacies of material handling and process complexity poses significant challenges for Metal Forming manufacturers. From selecting the right materials to optimizing tooling designs and minimizing setup times, addressing these challenges requires a holistic approach encompassing technology, expertise, and operational excellence.

2.3 Sustainable Practices and Regulatory Compliance: A Call to Action

In an era marked by growing environmental concerns and stringent regulatory mandates, sustainability has emerged as a critical imperative for the Metal Forming industry. Embracing sustainable practices, from reducing energy consumption to minimizing waste generation, not only aligns with regulatory standards but also fosters a positive brand image and enhances long-term viability.

The Role of Hydraulic Presses for Sale in Metal Forming

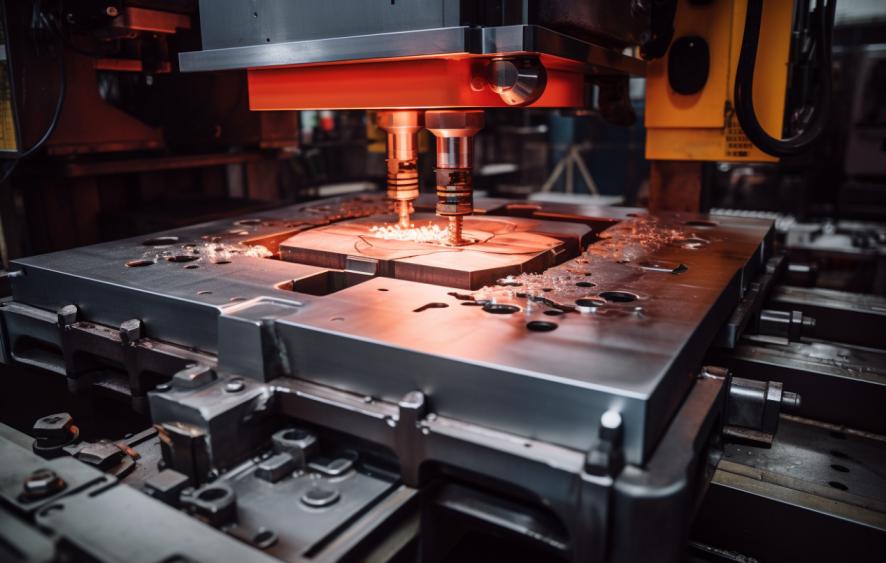

3.1 Introduction to Hydraulic Presses for Sale Technology: Powering Precision

At the heart of many Metal Forming operations lies hydraulic press technology, offering unmatched versatility and precision in shaping various metals. Hydraulic Presses for Sale leverages hydraulic cylinders to exert immense force, enabling manufacturers to achieve complex geometries and tight tolerances with unparalleled accuracy and efficiency.

3.2 Applications of Hydraulic Presses in Metal Forming: Versatility Unleashed

From deep drawing and blanking to forming and forging, hydraulic presses find diverse applications across the Metal Forming spectrum. Whether producing automotive body panels, aerospace components, or intricate metal parts for consumer electronics, hydraulic presses offer unparalleled versatility, making them indispensable assets for manufacturers across industries.

3.3 Efficiency Gains and Enhanced Safety: Driving Performance

The adoption of Hydraulic Presses for Sale systems translates into tangible benefits for Metal Forming manufacturers, including improved production efficiency, reduced downtime, and enhanced workplace safety. With features such as programmable control systems, advanced safety protocols, and ergonomic design, hydraulic presses empower operators to optimize performance while mitigating operational risks.

Trends Driving Adoption of Hydraulic Presses

4.1 Automation and Digitalization: Shaping the Future of Manufacturing

As the Metal Forming industry marches towards digital transformation, automation plays a pivotal role in enhancing efficiency and productivity. Hydraulic presses integrated with automation systems enable seamless operation, from material handling to part ejection, reducing manual intervention and minimizing production bottlenecks. The convergence of digitalization and hydraulic press technology unlocks new possibilities for optimizing manufacturing workflows and achieving unprecedented levels of precision.

4.2 Industry 4.0 Integration: Pioneering the Era of Smart Manufacturing

The rise of Industry 4.0 ushers in a new era of smart manufacturing, where interconnected systems and real-time data analytics drive decision-making and performance optimization. Hydraulic Presses for Sale equipped with IoT sensors, predictive maintenance capabilities, and cloud-based monitoring platforms empower manufacturers to monitor equipment health, preemptively address issues, and maximize uptime. The integration of Industry 4.0 technologies enhances operational visibility, fosters proactive maintenance strategies, and ultimately boosts overall equipment effectiveness (OEE).

4.3 Customization Options and Modular Designs: Tailoring Solutions to Unique Needs

In a market characterized by diverse product designs and material specifications, customization and flexibility are paramount. Hydraulic press manufacturers like GUANGDUAN offer a wide array of customization options, from tonnage capacity and bed size to stroke length and tooling configurations, allowing manufacturers to tailor solutions to their specific application requirements. Modular designs further enhance flexibility, enabling seamless integration of additional functionalities and future scalability as production needs evolve.

Advantages of Investing in Hydraulic Press Technology

5.1 Increased Production Throughput and Yield: Driving Operational Excellence

Hydraulic presses offer a quantum leap in production throughput and yield compared to traditional forming methods. With rapid cycle times, precise control over force and speed, and minimal setup requirements, hydraulic presses optimize production workflows, reduce lead times, and enhance overall equipment efficiency. The ability to achieve higher speeds and accuracies translates into increased output and improved yield, empowering manufacturers to meet growing demand while maintaining uncompromised quality standards.

5.2 Cost Savings and Operational Efficiency: Maximizing Returns on Investment

Beyond productivity gains, investing in hydraulic press technology delivers tangible cost savings across various operational aspects. Reduced scrap rates, attributed to precise control over forming processes and minimal material waste, translate into significant cost savings over time. Moreover, hydraulic presses boast energy-efficient designs and streamlined operations, minimizing energy consumption and operating costs. By optimizing resource utilization and minimizing downtime, hydraulic presses maximize returns on investment and bolster long-term competitiveness.

5.3 Flexibility to Accommodate Diverse Product Designs: Empowering Innovation

One of the standout advantages of Hydraulic Presses for Sale is their inherent flexibility to accommodate diverse product designs and material specifications. Whether forming intricate components for automotive, aerospace, or consumer electronics industries, hydraulic presses offer unmatched versatility, enabling manufacturers to explore new design possibilities and adapt to evolving market demands. From deep drawing and blanking to forming and embossing, hydraulic presses excel across a wide range of applications, providing manufacturers with the agility to innovate and differentiate in a competitive landscape.

Case Studies and Success Stories

6.1 Real-World Examples of Transformational Impact

The true testament to the power of hydraulic press technology lies in real-world success stories of Metal Forming manufacturers achieving remarkable results. Case studies showcasing notable improvements in productivity, product quality, and return on investment underscore the transformative impact of hydraulic presses on manufacturing operations. From doubling production throughput to slashing defect rates and achieving rapid payback periods, these success stories validate the compelling value proposition of hydraulic press solutions.

6.2 Testimonials from Satisfied Customers

Endorsements from satisfied customers further validate the performance and reliability of hydraulic press systems. From precision engineering firms to large-scale manufacturing facilities, testimonials highlight the unparalleled precision, efficiency, and durability of hydraulic presses from GUANGDUAN. Whether enhancing productivity, ensuring consistent quality, or maximizing profitability, hydraulic presses continue to earn praise from industry leaders and customers alike for their exceptional performance and reliability.

Conclusion: Embracing Innovation in Metal Forming

As the Metal Forming industry continues to evolve, embracing innovation and leveraging cutting-edge technologies will be paramount for manufacturers seeking to thrive in a fiercely competitive landscape. Hydraulic Presses for Sale stands as exemplars of precision and efficiency, offering a pathway to enhanced productivity, superior quality, and sustainable growth. In the pursuit of excellence, manufacturers must seize the opportunity to explore the vast potential of hydraulic press technology and chart a course toward a future defined by innovation and success.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us