How Does a Mechanical Press Work? Brings Precision to Life

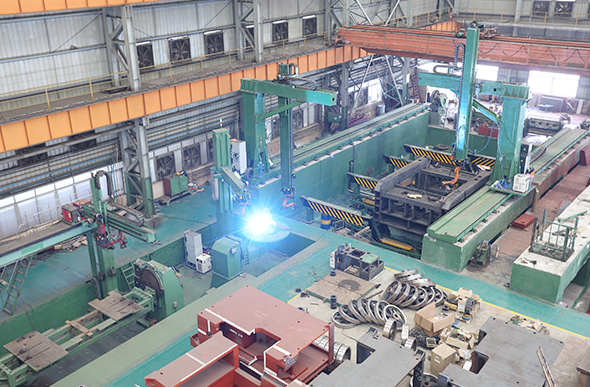

Visualize the immense force necessary to transform a flat, unremarkable metal sheet into a finely-crafted component destined for a car, household appliance, or intricate piece of machinery. In what ways do industries accomplish this transformation with the speed, power, and precise control that contemporary demands call for? The answer lies in the mechanical press—a powerful, meticulously-engineered machine that has earned its place as an essential tool in metalworking and industrial manufacturing. But what are the mechanics behind this machine, and why has it gained such a reputation for reliability? Let us delve into the complexities of a mechanical press, focusing on the How Does a Mechanical Press Work, state-of-the-art features of GUANGDUAN’s Mechanical Punch Press STPP Series.

A Deep Dive into the Mechanical Press: A Foundation of Precision Manufacturing

Defining a Mechanical Press

The mechanical press, specifically the mechanical punch press, is a specialized machine that molds metal sheets into specific, predetermined shapes. Its core function is rooted in precision—delivering highly accurate cuts through an intense, controlled force applied via a die. This cutting and shaping action enables manufacturers to produce vast numbers of identical parts swiftly, making it indispensable in industries such as automotive, electronics, and more. This machine, driven by a motor, relies on converting rotational energy into linear movement, a transformation that generates the necessary force to slice, bend, or compress metal into its intended form.

The Functioning Principle of a Mechanical Press

How Does a Mechanical Press Work? The operational principle behind mechanical presses may seem straightforward but it is remarkably effective. Essentially, the motor powers a flywheel that accumulates rotational energy. This energy is then channeled to a crankshaft connected to a slider, which secures the press’s punch. When engaged, the crankshaft drives the slider downward, moving the punch toward the die positioned beneath it. The coordinated movement of the punch and die manipulates the metal sheet, creating cuts or bends in accordance with the die’s specific design.

Why Opt for a Mechanical Punch Press?

One of the primary advantages of choosing a mechanical punch press over other varieties, like hydraulic presses, lies in its efficiency. Unlike hydraulic presses, which function through pressurized fluids, mechanical presses typically operate at higher speeds and are more suitable for rapid production cycles. This capability is invaluable in high-volume manufacturing, where every moment counts. Additionally, mechanical presses deliver a stable force output, which is crucial for maintaining uniform precision over large quantities of parts.

In-Depth Look at the Mechanical Punch Press STPP Series: Leading Metal Press Innovation

Structural Strength for Operational Stability

How Does a Mechanical Press Work? The Mechanical Punch Press STPP Series stands out due to its highly durable body construction. The frame is built by welding steel plates, which bestows it with remarkable rigidity and durability. This sturdiness is crucial in mitigating vibrations during high-speed operations, thereby ensuring consistent and precise performance with each press. Furthermore, the robust structure not only lengthens the machine’s operational lifespan but also reduces maintenance requirements, offering economic advantages for operators over time.

Reverse Double Crankshaft Design for Improved Balance

A unique aspect of the STPP Series is its double crankshaft design, arranged in a reverse configuration. This innovative design enhances balance by counteracting the lateral forces generated during pressing operations. In conventional presses, these forces can disrupt motion balance, diminishing precision and causing uneven wear on specific components. With a reverse double crankshaft, however, the STPP Series mitigates these forces, fostering a stable motion that leads to smoother, more accurate punching actions.

Achieving Precision in Motion: The Role of Eight-Sided Full Guide Rails

The STPP Series boasts eight-sided full guide rails that meticulously guide the slider’s movement. This advanced guide rail structure serves multiple essential functions:

Improved Accuracy: The eight-sided configuration allows the slider to follow a strictly controlled path, minimizing any lateral deviation. Such accuracy is critical for applications requiring exact cuts and consistency across extensive production runs.

Enhanced Capacity for Unbalanced Loads: With its guide rails, the STPP Series can more effectively handle unbalanced loads compared to traditional mechanical presses, reducing the risk of misalignment or deflection during operation.

Increased Longevity: The guide system minimizes lateral stress on the slider, reducing component wear and thereby extending the press’s service life.

Key Technological Features of the STPP Series Mechanical Punch Press

Hydraulic Overload Protection for Sensitivity and Safety

The STPP Series incorporates an internal hydraulic overload protection device within the slide block. This system offers dual protection for both the machinery and operators by responding swiftly to overloads, thus preventing potential damage or operational failure. This hydraulic protection device is exceptionally responsive, safe, and reliable. When it detects a force beyond safe operating limits, it disengages instantly, safeguarding the entire press system and enhancing operator safety.

High-Torque Wet Clutch for Dependable Performance

Another significant feature of the STPP Series is its high-torque wet clutch. Designed to deliver substantial torque, this clutch type avoids many of the issues associated with traditional clutches. Wet clutches operate with the help of lubricants, which not only reduce wear but also prolong service life and lead to quieter operations. Additionally, this feature enhances responsiveness, allowing the press to start and stop with precision—an asset for applications that demand exact, repeatable stamping actions.

PLC Control System for Enhanced Automation and Efficiency

The STPP Series leverages a Programmable Logic Controller (PLC) control system to optimize productivity. This system supports automation by integrating auxiliary devices, such as uncoiling and leveling mechanisms, into the production line. By utilizing PLC control, manufacturers can automate individual presses as well as entire production lines, maximizing efficiency. With PLC technology, the STPP Series can seamlessly adjust to various production requirements, providing versatility and reliability in dynamic manufacturing settings.

Why the STPP Series Mechanical Punch Press Stands Out

Exceptional Precision for High-Stakes Applications

The STPP Series is a top choice for applications where precision is paramount. Its eight-sided guide rail system, balanced double crankshaft structure, and overall superior build quality enable this mechanical press to deliver high-precision cuts consistently. This feature makes it ideal for industries such as automotive, electronics, and consumer goods manufacturing, where even minimal dimensional variations can compromise overall product quality.

Robustness and Minimal Maintenance Needs

Built with a sturdy design, a dependable wet clutch, and hydraulic overload protection, the STPP Series is engineered for long-term durability. Its robust construction and thoughtful engineering minimize wear on parts, resulting in reduced maintenance costs and fewer service interruptions. This longevity is a valuable benefit for manufacturers aiming to maximize operational uptime and minimize costs.

Enhanced Operator Safety and Environmental Benefits

The STPP Series’ hydraulic overload protection and wet clutch offer additional safety benefits. These features protect both the operators and the machinery itself, while the wet clutch design reduces noise pollution, creating a quieter, more comfortable workplace. This dedication to safety and eco-friendly operation makes the STPP Series a smart investment for modern production facilities focused on sustainable practices.

In Conclusion: The Mechanical Punch Press STPP Series as a Future-Ready Solution

The Mechanical Punch Press STPP Series by GUANGDUAN embodies the precision and innovation that define a modern mechanical press. By merging advanced engineering with user-centric controls and automated production capabilities, it stands out as an essential tool in the metalworking industry. Whether the need is for high-volume part production or precision in complex applications, this series achieves an impressive balance of power, precision, and durability.

The STPP Series transcends merely pressing metal; it symbolizes the delivery of consistent quality, efficiency, and reliability that today’s competitive manufacturing landscape demands. Its carefully designed features and innovations showcase how the right mechanical press can revolutionize production processes, establishing a new standard for accuracy and resilience with each precisely executed punch.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us