Unlock Your Potential with Horizontal Hydraulic Press Technology!

Are you looking to unlock your potential with the newest technology? Horizontal hydraulic presses are the answer! This type of press uses hydraulic power to move large objects and materials, allowing you to complete complex tasks with ease. In this article, we’ll discuss what horizontal hydraulic presses are, the benefits they offer, different types of presses, how they work, safety considerations, common applications, and more. Read on to learn why horizontal hydraulic presses are the best choice for unlocking your potential.

Introduction to Horizontal Hydraulic Presses

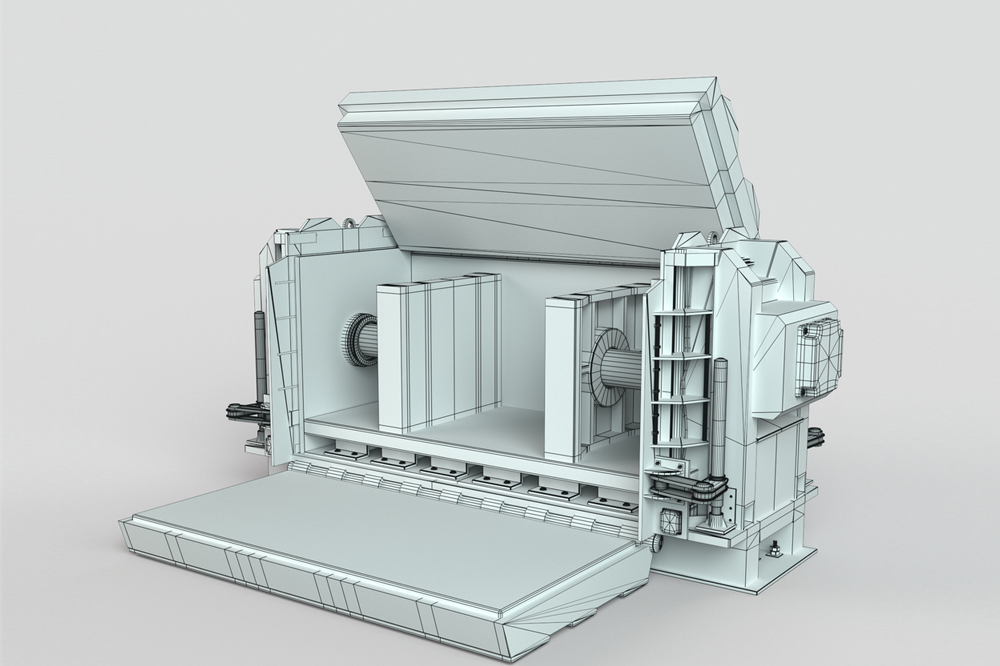

Horizontal hydraulic presses are pieces of industrial machinery that use hydraulic power to move large objects and materials. They are typically used to shape, cut, and form materials, such as metals, plastics, and composites. Hydraulic presses are incredibly powerful and allow for a wide variety of tasks to be completed quickly and efficiently.

These presses have been around for centuries, but in recent years, the technology has been improved to make them even more powerful and efficient. Now, horizontal hydraulic presses are used in a variety of industries, including automotive, aerospace, medical, food processing, and more.

The Benefits of Horizontal Hydraulic Presses

Horizontal hydraulic presses offer a wide range of benefits that make them the ideal choice for industrial applications. Here are just a few of the advantages they offer:

- Durability: Horizontal hydraulic presses are incredibly durable and can withstand the most demanding conditions. Their construction is designed to last for many years, so you can be sure that your press will remain in top condition for a long time.

- Versatility: Horizontal hydraulic presses are extremely versatile, allowing you to complete a wide range of tasks with the same piece of equipment. Whether you need to cut, shape, or form materials, you can do it all with the same press.

- Speed and Efficiency: Hydraulic presses are incredibly fast, allowing you to complete tasks quickly and efficiently. This means that you can get more done in less time, which translates to increased productivity and cost savings.

Different Types of Horizontal Hydraulic Presses

There are several different types of horizontal hydraulic presses, each of which offers different benefits and features. Here are some of the most common types:

- Single-Acting Presses: Single-acting presses use one cylinder to move materials. They are typically used for small-scale jobs and are ideal for short-term use.

- Double-Acting Presses: Double-acting presses use two cylinders to move materials. They are typically used for larger jobs and can handle more pressure than single-acting presses.

- Four-Post Presses: Four-post presses use four cylinders to move materials. They are typically used for heavier jobs, such as metal forming and pressing, and can handle more pressure than double-acting presses.

How Horizontal Hydraulic Presses Work

Horizontal hydraulic presses use hydraulic power to move materials. This power is generated by a pump, which forces fluid (usually oil) through a series of valves. This fluid then moves through a cylinder, which is connected to a piston. As the fluid moves through the cylinder, it forces the piston to move, which in turn moves the materials that are being pressed.

The amount of force that is applied to the materials is determined by the amount of pressure that is applied to the fluid. The pressure can be adjusted, allowing you to control the force that is applied to the materials. This makes it easy to tailor the press to your specific needs.

Safety Considerations When Using Horizontal Hydraulic Presses

When using horizontal hydraulic presses, it’s important to keep safety in mind. Here are a few safety considerations to keep in mind:

- Wear the appropriate safety gear: It’s important to wear the appropriate safety gear when operating a hydraulic press. This includes safety glasses, gloves, and protective clothing.

- Understand the hazards: Make sure that you understand the potential hazards associated with using a hydraulic press. This includes understanding the safety mechanisms of the press and being aware of the potential for hydraulic fluid leakage.

- Have proper ventilation: Make sure that the area where the press is being used is properly ventilated. This will ensure that any potential hazardous fumes are properly vented.

Common Applications of Horizontal Hydraulic Presses

Horizontal hydraulic presses are used in a variety of industries for a wide range of applications. Here are some of the most common applications:

- Automotive: Hydraulic presses are often used in the automotive industry for stamping, forming, and pressing metal parts.

- Aerospace: Hydraulic presses are used in the aerospace industry to form and press composite materials into various shapes.

- Medical: Hydraulic presses are often used in the medical industry to form and press medical-grade plastics into various shapes.

- Food Processing: Hydraulic presses are used in the food processing industry to press and shape food products.

Advantages of Horizontal Hydraulic Presses

Horizontal hydraulic presses offer a number of advantages that make them the ideal choice for industrial applications. Here are some of the advantages they offer:

- Precision: Hydraulic presses are incredibly precise, allowing you to shape and form materials with incredible accuracy.

- Cost-Effective: Horizontal hydraulic presses are surprisingly cost-effective, allowing you to get the job done without breaking the bank.

- Flexibility: Hydraulic presses are incredibly flexible, allowing you to adjust the pressure and speed to suit your specific needs.

- Easy to Operate: Hydraulic presses are easy to operate, allowing you to get the job done quickly and efficiently.

How to Choose the Right Horizontal Hydraulic Press

When choosing a horizontal hydraulic press, it’s important to consider your specific needs. Here are a few things to consider:

- Size: The size of the press should be determined by the size of the materials that you need to press. Make sure that the press is large enough to handle the materials that you need to press.

- Pressure: Consider the amount of pressure that you need the press to be able to generate. If you need to press heavy materials, you’ll need a press that can generate a high amount of pressure.

- Speed: Consider the speed that you need the press to be able to operate at. If you need to press materials quickly, you’ll need a press that can operate at a high speed.

Pre-Purchase Considerations for Horizontal Hydraulic Presses

Before you purchase a horizontal hydraulic press, it’s important to consider a few things. Here are some pre-purchase considerations:

- Budget: Make sure that you have a clear budget in mind before you purchase a press. This will help ensure that you don’t overspend.

- Installation: Consider the installation process of the press. Some presses may require professional installation, so it’s important to factor this into your budget.

- Maintenance: Make sure that you understand the maintenance requirements of the press. Regular maintenance is essential for keeping the press in top condition.

Conclusion

Horizontal hydraulic presses are incredibly powerful pieces of machinery that can help you unlock your potential. They offer a wide range of benefits, such as durability, versatility, and speed. Additionally, they are used in a variety of industries for a wide range of applications. When choosing a press, it’s important to consider your specific needs and budget. With the right press, you’ll be able to complete complex tasks quickly and efficiently. So what are you waiting for? Unlock your potential with horizontal hydraulic press technology today!

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us