How Forging Press Guangduan Transforms Modern Manufacturing

Captivating Beginnings: What Drives the Future of Metal Manufacturing?

Imagine a world where the automotive components of tomorrow are crafted with unparalleled precision, ensuring safety and performance. Did you know that the global demand for high-quality metal parts is expected to double in the next decade? As industries evolve, the need for advanced forging press machines becomes more critical than ever. This is where Forging Press Guangduan steps in, revolutionizing the manufacturing landscape with innovative solutions tailored to meet diverse industrial challenges.

Navigating Industrial Challenges with Cutting-Edge Solutions

The Ever-Changing Landscape of Metal Manufacturing

The metal manufacturing industry is continuously adapting to meet the rising standards of quality, efficiency, and sustainability. Manufacturers face numerous challenges, including increasing production speeds, maintaining stringent quality controls, and minimizing waste. Additionally, the integration of automation and smart technologies demands machinery that can keep pace with these advancements. Forging Press Guangduan addresses these challenges head-on, offering state-of-the-art forging press machines that enhance productivity and ensure consistent quality.

Trends Shaping the Future of Product Processing

Modern manufacturing is witnessing significant trends that are reshaping product processing. Precision engineering, automation, and digital integration are at the forefront, driving the need for machinery that can deliver high accuracy and flexibility. Furthermore, the push towards sustainable manufacturing practices emphasizes the importance of energy-efficient and environmentally friendly equipment. Forging Press Guangduan stays ahead of these trends by developing machines that incorporate advanced control systems, energy-efficient designs, and versatile functionalities to meet the evolving demands of the industry.

Meeting Special Project Needs with Versatility and Reliability

Every industrial project has its unique set of requirements, whether it’s producing intricate automotive parts or large-scale machinery components. Forging Press Guangduan excels in providing customized solutions that cater to these specific needs. Their range of forging press machines, including the renowned JH31 Series, is designed to handle a wide variety of applications with precision and reliability. By offering tailored configurations and adaptable features, Forging Press Guangduan ensures that each project is executed flawlessly, regardless of its complexity or scale.

The JH31 Series: A Pinnacle of Forging Technology

Unmatched Structural Integrity for Superior Performance

The Closed Type Single Point Forge Press Machine JH31 Series stands out in the market due to its robust construction. Manufactured using a monolithic box-type structure, the JH31 series boasts high rigidity, ensuring stable and precise operation even under heavy loads. Some models feature a four-pull level pre-light structure, further enhancing the machine’s structural integrity. This design not only improves the machine’s durability but also contributes to consistent performance, making it a reliable choice for demanding industrial applications.

Advanced Mechanical Features for Enhanced Precision

Precision is paramount in metal forging, and the JH31 series delivers exceptional accuracy through its sophisticated mechanical features. The type eccentric crankshaft offers strong bearing capacity, ensuring smooth and stable motion. Additionally, the wet-type clutch extends the machine’s service life by reducing wear and tear. The four-surface full-guideway slide block provides high guiding precision and excellent holding precision, enabling intricate and detailed forging processes with minimal deviation. These advanced features collectively ensure that every forged part meets the highest standards of quality and precision.

Smart Control Systems for Seamless Operation

The JH31 series integrates modern control technologies to streamline operations and enhance user experience. Equipped with a combination of PLC and pneumatic control modes, the machine offers versatile stroke specifications, including continuous stroke, single stroke, and micro-motion. This flexibility allows operators to adjust the forging process to match specific project requirements seamlessly. Additionally, the machine features digital die set height adjustment, facilitating easy and rapid die calibration. Safety and automation are also prioritized, with options for photo-electric protection and automated feeding and uncoiling leveling devices, ensuring both reliability and efficiency in production.

Features That Set the JH31 Series Apart

Intelligent Safety and Protection Mechanisms

Safety is a critical concern in industrial environments, and the JH31 series is designed with comprehensive protection features to ensure secure operation. The JH31-400/630/800 models are equipped with hydraulic overload protective devices, safeguarding the machine against excessive loads and potential damage. Meanwhile, the JH31-200-300 models feature a wedge-shaped iron die unlocking device, enhancing operational safety during die changes. Additionally, the option to incorporate photo-electric protection systems adds an extra layer of security, preventing accidents and ensuring a safe working environment for operators.

Effortless Die Calibration and Adjustment

Efficient die calibration is essential for maintaining high-quality production and minimizing downtime. The JH31 series addresses this need with its mechanically adjusted, digitally displayed die set height. This feature allows for precise and swift adjustments, enabling operators to calibrate dies quickly and accurately. The ease of die calibration not only enhances production efficiency but also ensures consistent quality across all forged parts. Whether dealing with small-scale batches or large production runs, the JH31 series facilitates smooth and reliable die management.

Versatile Control Modes for Diverse Applications

The JH31 series offers unparalleled versatility through its multiple control modes. Operators can choose between continuous stroke, single stroke, and micro-motion options to suit various forging requirements. This adaptability makes the JH31 series suitable for a wide range of applications, from high-volume production to specialized, intricate forging tasks. The seamless integration of PLC and pneumatic controls ensures that the machine can handle diverse processing needs with ease, providing manufacturers with the flexibility to tackle different projects without compromising on performance or quality.

Expanding Horizons: Applications of Forging Press Machines

Automotive Industry: Driving Innovation and Safety

In the automotive sector, precision and reliability are crucial for producing components that ensure vehicle safety and performance. Forging press machines like the JH31 series play a vital role in manufacturing high-strength parts such as crankshafts, connecting rods, and suspension components. These machines deliver the necessary force and accuracy to produce parts that meet stringent industry standards, contributing to the overall quality and safety of vehicles. As the automotive industry continues to innovate with new materials and technologies, Forging Press Guangduan remains a key partner in driving these advancements forward.

Consumer Goods and Daily Hardware: Enhancing Durability and Functionality

Beyond heavy industries, forging press machines are integral to the production of everyday consumer goods and hardware. From kitchen appliances to hand tools, the precision and efficiency of machines like the JH31 series ensure that each product is durable and functional. The ability to produce intricate shapes and consistent quality makes these forging presses indispensable in creating reliable and long-lasting products. As consumer expectations for quality and performance rise, Forging Press Guangduan’s advanced machinery supports manufacturers in meeting these demands effectively.

Industrial Machinery and Gas Appliances: Building Robust and Reliable Components

In sectors such as industrial machinery and gas appliances, the need for robust and reliable components is paramount. Forging press machines are essential for creating parts that can withstand high pressures and demanding operational conditions. The JH31 series excels in producing these critical components with precision and strength, ensuring that industrial machinery and gas appliances operate smoothly and safely. By providing high-quality forging solutions, Forging Press Guangduan helps manufacturers maintain the integrity and performance of their products, contributing to overall industry reliability.

Forging Press Guangduan: A Legacy of Excellence and Innovation

A Heritage of Expertise and Technological Advancement

Founded in 1958, Forging Press Guangduan has built a legacy of excellence over more than six decades. As one of China’s leading manufacturers of forging and press machines, Guangduan has continually evolved by integrating cutting-edge technologies into its product offerings. With over 60 years of experience, the company has mastered the art of developing advanced metal stamping solutions that cater to a wide range of industrial needs. This rich heritage of expertise and innovation positions Forging Press Guangduan as a trusted partner in the forging and pressing industry.

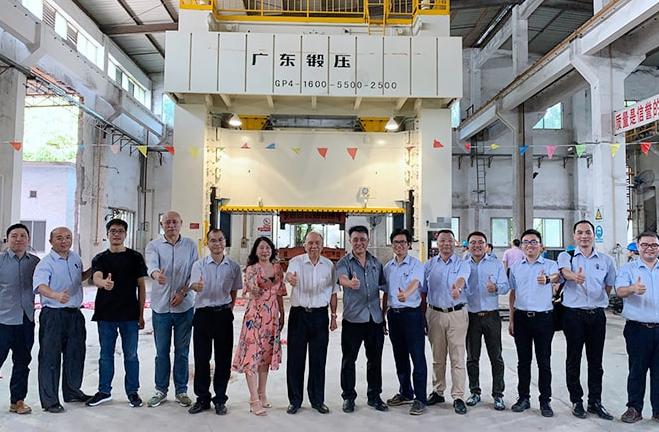

Comprehensive Facilities and Robust Capabilities

Forging Press Guangduan boasts a processing workshop spanning over 30,000 square meters, equipped with state-of-the-art machinery and a crane with a capacity of up to 125 tons. These robust facilities enable the company to handle large-scale production and complex forging projects with ease. Additionally, Guangduan employs over 800 experienced professionals who bring a wealth of knowledge and skills to the manufacturing process. The combination of expansive facilities and a skilled workforce ensures that Forging Press Guangduan can deliver high-quality machines that meet the diverse needs of its global clientele.

Commitment to Quality and Customer Satisfaction

Quality is at the heart of Forging Press Guangduan’s operations, as evidenced by its ISO 9001 certifications and recognition as a national high-tech enterprise. The company’s dedication to maintaining stringent quality standards ensures that every forging press machine leaving the factory meets the highest levels of performance and reliability. Moreover, Guangduan places a strong emphasis on customer service, with a quick response after-sales team ready to support clients promptly and effectively. This commitment to quality and customer satisfaction has earned Forging Press Guangduan a stellar reputation as one of the top forging and press machine manufacturers in Southern China.

Embracing the Future with Forging Press Guangduan

Pioneering Metal Stamping Solutions for Tomorrow’s Industries

As industries continue to advance and new challenges emerge, Forging Press Guangduan remains at the forefront of innovation in the forging and pressing sector. By continuously developing cutting-edge technologies and expanding its product range, Guangduan ensures that it can meet the evolving needs of its customers. Whether it’s enhancing existing manufacturing processes or pioneering new forging techniques, Forging Press Guangduan is dedicated to providing solutions that drive progress and foster industrial growth.

Sustainable Manufacturing and Environmental Responsibility

In today’s world, sustainable manufacturing practices are more important than ever. Forging Press Guangduan is committed to minimizing its environmental footprint by developing energy-efficient machines and implementing eco-friendly production processes. By prioritizing sustainability, the company not only contributes to environmental preservation but also helps its clients achieve their own sustainability goals. This dedication to responsible manufacturing underscores Forging Press Guangduan’s role as a forward-thinking leader in the forging and pressing industry.

Building Stronger Partnerships for Global Success

Forging Press Guangduan’s success is built on strong partnerships with clients worldwide. By understanding the unique needs of each customer and providing tailored solutions, Guangduan fosters long-term relationships that drive mutual growth and success. The company’s extensive network and global reach enable it to support clients in various industries across different regions, ensuring that its forging press machines contribute to the success of businesses around the world. As Forging Press Guangduan continues to expand its horizons, it remains dedicated to building stronger partnerships that pave the way for a prosperous future in metal manufacturing.

Conclusion: Forging Ahead with Guangduan

In an era where precision, efficiency, and adaptability are paramount, Forging Press Guangduan stands out as a beacon of innovation and reliability. From overcoming industrial challenges to embracing the latest trends in product processing, Guangduan’s advanced forging press machines like the JH31 series empower manufacturers to achieve excellence in their operations. With a rich heritage, comprehensive capabilities, and an unwavering commitment to quality and customer satisfaction, Forging Press Guangduan is not just a supplier but a trusted partner in shaping the future of metal manufacturing.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us