How Hydraulic Press Equipment Enhance Precision in Aerospace Stamping

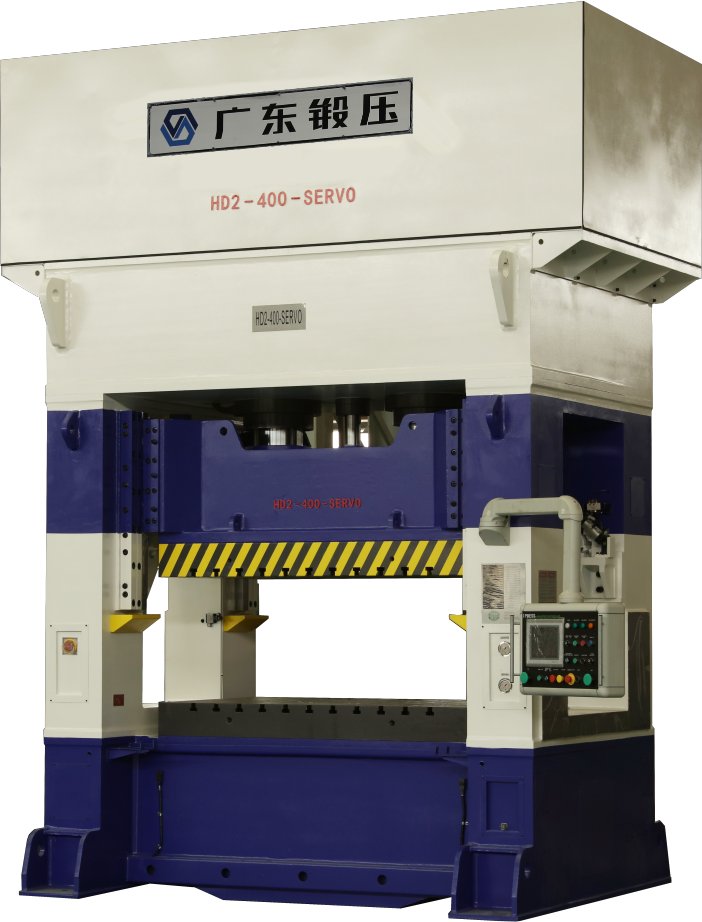

Precision in aerospace manufacturing is essential, with over 50% of aerospace accidents linked to component failures. Stamping plays a significant role in producing critical parts, such as fuselage sections, wings, and engine components. Hydraulic press equipment is integral to modern aerospace stamping, with the GY2S Series specifically designed for this application. The fuselage’s main structural parts are made from high-quality steel welded into a box structure, providing up to 30% greater rigidity compared to traditional designs. This structure offers improved aesthetic appeal and is easier to transport, with weight reductions of up to 20%. The slider is also constructed from a steel plate welded box structure, utilizing eight-sided full guide rail guides, ensuring a precision level within 0.01mm. Additionally, the system includes thin oil continuous circulation lubrication, boosting performance by up to 15% by reducing friction and wear.

The Demands of Aerospace Stamping

Complexities and High Standards Required for Aerospace Parts

Aerospace parts require strict standards. Tolerances must be precise. The materials need to be durable. Parts also have to be lightweight. These factors make the process more complicated. Precision is key. Each part must meet specific weight and strength requirements.

The Pressure to Meet Tight Specifications

Aerospace stamping faces a lot of pressure. Manufacturers need to meet tight specifications. They must do this consistently over large volumes. Even small mistakes can affect safety. Keeping up with these demands is challenging. High-quality parts must be produced repeatedly. This adds stress to the production process.

The Basics of Hydraulic Press Equipment

Explanation of Hydraulic Presses and Their Key Components

A hydraulic press uses fluid pressure. It shapes and molds metal. It is made of several key parts. These include the press frame, hydraulic cylinders, and pump systems. The press also has a control unit. The system operates by pushing fluid into cylinders. This force is then used to mold the material.

How They Operate

The hydraulic press works by using fluid pressure. The press forces the fluid into the cylinders. The pressure builds up and moves the press’s piston. This action molds the metal into the desired shape. The process can be controlled with great precision.

Comparison to Mechanical Presses and Why Hydraulic Presses Are Preferred for Precision

Hydraulic presses are different from mechanical presses. Mechanical presses rely on a flywheel and a clutch system. Hydraulic presses, on the other hand, use fluid. The fluid allows for smooth and controlled movements. This makes hydraulic presses better for precision work. They can also apply force gradually, which is important for some materials.

Guangduan‘s Technological Advancements in Hydraulic Press Systems

Main Structural Parts of the Fuselage Made of High-Quality Steel

The fuselage is made from strong, high-quality steel. This steel has a welded box structure. The structure provides good rigidity. It also has a clean and attractive appearance. Because of the design, the fuselage is easy to transport.

The Slider Uses a Steel Plate Welded Box Structure

The slider in the press is made of a steel plate welded box structure. It is supported by an eight-sided guide rail. This structure offers precision. It helps the machine maintain its accuracy over time.

Thin Oil Continuous Circulation Lubrication System

The machine uses a thin oil circulation system for lubrication. This system works continuously. It ensures that all parts of the press are well-lubricated. This reduces friction and wear.

The Servo Closed Loop Control System

The press uses a servo closed-loop control system. This system includes a servo motor driver. It also uses a pressure sensor and displacement sensor. A PLC is used to manage the system. The system offers high precision. It also produces low noise and vibration. It saves energy and is environmentally friendly.

Intelligent Control and High Operability

The system uses an intelligent control method. It combines a PLC servo system and a touch screen. The control system is very user-friendly. Operators can make real-time digital adjustments using the touch screen. The system can store up to 20 different mold settings. This makes it easy to adjust the press for different production processes.

High Security

The press has strong safety features. It includes a slider locking device. This device prevents the slider from moving unexpectedly. The press also has a lower limit switch for safety. There is a two-handed anti-repetition system. Multiple levels of protection are included. These protect against errors and improve operator safety.

How Hydraulic Press Equipment Improves Precision

Control and Consistency

Hydraulic systems offer smoother movements. They are more controlled. This helps reduce variations in the force applied. As a result, the parts are more accurate. There is less chance for errors.

Force Modulation

Hydraulic presses can adjust the pressure applied. The amount of force can be varied during each cycle. This allows for better shaping of the material. The force is applied gradually. This is important for achieving the desired shape.

Complex Geometries

Hydraulic presses can produce complex shapes. They are ideal for parts with intricate designs. These parts may have tight tolerances. Hydraulic presses can achieve high accuracy, which is necessary for aerospace components.

Repeatability

Hydraulic presses provide high precision over large volumes. This means parts can be produced repeatedly with the same accuracy. This improves consistency. It also reduces defects, which helps increase yield rates.

The Impact on Aerospace Manufacturing

Improved Part Quality

Hydraulic presses improve part quality. They reduce the number of defective parts. This lowers the need for rework. The result is higher quality aerospace components.

Increased Efficiency

Hydraulic presses improve efficiency. The production cycles are faster. Yet, accuracy is not sacrificed. The machines can operate quickly without compromising on quality.

Cost Savings

Using hydraulic presses leads to cost savings. There are fewer defective parts. This lowers scrap rates. Material wastage is also reduced. Together, these factors lead to more cost-effective manufacturing.

Unlock Precision in Aerospace Manufacturing Today

Want to improve your aerospace manufacturing? Guangduan Hydraulic presses offer high precision, control, and efficiency. They handle complex parts with ease. With better quality and faster production, you’ll meet tight deadlines. Reduce waste and save costs. Upgrade to advanced hydraulic press systems. Invest in technology that boosts performance. Start improving your production process now.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us