Customized Forging Press for Sale Solutions for Specialized Metal Products

Picture a lively factory environment where metal parts are meticulously shaped with both accuracy and speed, propelling various industries forward. Are you aware that the appropriate Forging Press for Sale can enhance production output by as much as 30%? Forging presses serve as the fundamental infrastructure for numerous industrial metal manufacturing processes, facilitating the production of everything from automotive components to aerospace parts. This blog delves into the realm of customized and budget-friendly Forging Press for Sale solutions available for purchase, with a particular emphasis on GUANGDUAN’s outstanding market offerings.

Customized Forging Press for Sale Solutions for Specialized Metal Products

Grasping the Distinct Requirements of Metal Manufacturing

Each metal product manufacturing line possesses its own unique set of requirements. Whether it involves the delicate intricacies of aerospace components or the sturdy construction of automotive parts, the forging process must be carefully customized to meet specific demands. Off-the-shelf forging presses frequently fail to address these specialized needs, resulting in inefficiencies and diminished quality. Manufacturers need presses that not only align with their production volumes but also adapt to the unique properties of the metals being forged.

Customization in forging presses guarantees that every machine is capable of handling the particular challenges associated with different metal products. This encompasses modifications in pressure capacity, die configurations, and operational speeds to optimize the forging process. By catering to these unique specifications, customized forging presses improve overall production quality and efficiency, enabling manufacturers to sustain a competitive advantage within their respective industries.

Furthermore, specialized metal products often require heightened precision and consistency. Customized Forging Press for Sale is engineered with advanced features that offer enhanced control over forging parameters, ensuring that each component adheres to stringent quality standards. This level of precision is vital for sectors where safety and reliability are critical, such as aerospace and automotive manufacturing.

Tailored Solutions Offered by GUANGDUAN

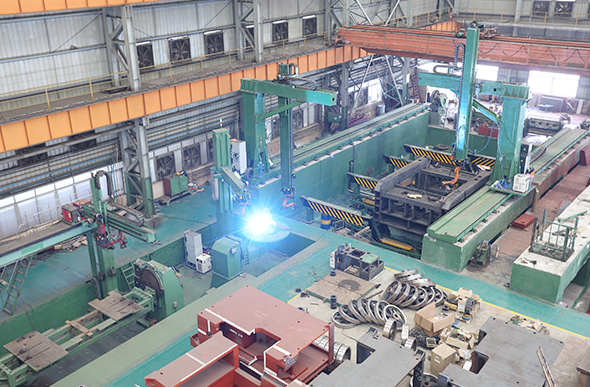

GUANGDUAN distinguishes itself as a leading supplier of Forging Press for Sale by providing tailored solutions that address the specific needs of various metal product manufacturers. With a profound understanding of the diverse requirements across different industries, GUANGDUAN designs and manufactures forging presses that are both versatile and robust. Their dedication to customization ensures that each press is fine-tuned for its intended application, whether it involves heavy-duty forging for construction materials or precise forging for intricate metal parts.

The company engages closely with clients to comprehend their unique production challenges and objectives. This collaborative methodology enables GUANGDUAN to develop forging presses that not only meet but surpass customer expectations. From selecting the appropriate capacity and size to integrating sophisticated control systems, GUANGDUAN ensures that each forging press is meticulously aligned with the client’s operational requirements.

GUANGDUAN’s extensive portfolio includes a variety of forging presses, notably their esteemed Knuckle Joint Press GK Series. These presses are meticulously engineered to deliver exceptional performance and reliability, making them the preferred choice for manufacturers seeking customized forging solutions. By leveraging state-of-the-art technology and innovative design, GUANGDUAN provides forging presses that enhance production capabilities and drive industrial success.

Benefits of Customized Forging Presses

Investing in customized Forging Press for Sale presents numerous advantages that profoundly influence production quality and efficiency. One of the primary benefits is the ability to attain higher precision in the forging process. Customized presses are designed to accommodate specific die configurations and operational parameters, ensuring that each forged component meets exact specifications. This level of precision is crucial for maintaining consistency and quality across extensive production volumes.

Another significant advantage is the increased flexibility that customized forging presses offer. Manufacturers can adjust their production processes to meet varying demands and product specifications without necessitating substantial downtime or additional investments. This flexibility facilitates more efficient production scheduling and the capacity to swiftly respond to market fluctuations or customer requirements.

Additionally, customized forging presses often incorporate advanced features and technologies that boost overall operational efficiency. These may include automated control systems, real-time monitoring capabilities, and energy-efficient components that lower operational costs. By optimizing these aspects, manufacturers can achieve higher throughput rates while minimizing waste and resource consumption, ultimately leading to enhanced profitability and sustainability.

Affordable Forging Presses for Sale: Quality Solutions for Every Budget

The Significance of Affordability in Industrial Equipment

In the fiercely competitive industrial landscape of today, affordability plays a pivotal role for manufacturers when selecting forging presses. Budget limitations are a common hurdle, particularly for small to medium-sized enterprises striving to scale their operations without incurring prohibitive costs. Affordable forging presses present a viable solution, enabling businesses to invest in essential equipment without sacrificing quality or performance.

Cost-effective Forging Press for Sale ensures that manufacturers can upgrade their production capabilities without imposing significant financial burdens. This accessibility is essential for businesses aiming to enhance their manufacturing processes, expand their product lines, or penetrate new markets. By providing affordable options, suppliers like GUANGDUAN make advanced forging technology accessible to a wider array of manufacturers, thereby fostering industry growth and innovation.

Moreover, affordability in forging presses does not equate to compromised quality. With the right supplier, manufacturers can acquire high-performance equipment that delivers reliable results while adhering to budgetary constraints. This equilibrium between cost and quality is crucial for maintaining competitive pricing and ensuring long-term operational sustainability.

Quality Solutions Provided by GUANGDUAN

GUANGDUAN excels in offering affordable Forging Press for Sale without compromising on quality, thereby making high-performance forging solutions accessible to manufacturers across various budget ranges. Their GK Series knuckle joint presses exemplify this commitment, presenting a range of capacities and sizes to accommodate different production needs and financial plans. By optimizing manufacturing processes and utilizing cost-effective materials and technologies, GUANGDUAN ensures that their forging presses provide exceptional value for money.

The GK Series encompasses models with capacities ranging from 6300KN to 25000KN and bolster sizes from 700700mm to 12001200mm. This extensive range allows manufacturers to select a press that precisely aligns with their production requirements and budget. Whether a business operates on a tight budget or seeks to invest in high-capacity machinery, GUANGDUAN offers forging presses that cater to diverse financial and operational needs.

In addition to offering a broad spectrum of capacities, GUANGDUAN emphasizes the integration of advanced features that enhance the performance and longevity of their forging presses. Features such as precise die height indicators, integrated friction clutch brakes, and PLC-controlled systems ensure that each press operates efficiently and reliably. These quality solutions empower manufacturers to achieve high production standards while effectively managing costs, making GUANGDUAN a trusted partner for affordable forging presses.

Case Study: Knuckle Joint Press GK Series

The Knuckle Joint Press GK Series by GUANGDUAN serves as a quintessential example of forging presses that are both affordable and high in quality. This series offers a versatile range of capacities from 6300KN to 25000KN, rendering it suitable for a myriad of industrial applications. The available bolster sizes, ranging from 700700mm to 12001200mm, provide the necessary flexibility to accommodate different die sizes and forging requirements.

One of the standout features of the GK Series is its structural design. Knuckle joint presses with capacities from 4000KN to 16000KN utilize an integral structure, ensuring robust performance and durability. For higher capacities, the 12000KN model incorporates a split structure design, enhancing its versatility and ease of maintenance. This thoughtful engineering allows the GK Series to meet the diverse needs of manufacturers, from small-scale operations to large industrial facilities.

The GK Series also boasts advanced braking systems tailored to different models. The GK-630 series employs a pneumatic wet integrated friction clutch brake, delivering smooth and reliable operation. Conversely, the GK-800 to GK-2500 models feature a pneumatic dry split friction clutch brake, offering enhanced performance and control. These specialized braking systems contribute to the overall efficiency and safety of the forging process, making the GK Series a top choice for manufacturers seeking affordable, high-quality forging presses.

Knuckle Joint Press GK Series: The Ideal Combination of Performance and Reliability

Cutting-Edge Features of the GK Series

GUANGDUAN’s Forging Press for Sale GK Series knuckle joint presses are outfitted with an array of advanced features that distinguish them in the marketplace. A notable feature is the pneumatic wet integrated friction clutch brake incorporated in the GK-630 series. This braking system ensures smooth deceleration and precise control during the forging process, thereby enhancing overall operational efficiency and safety. For models ranging from GK-800 to GK-2500, the pneumatic dry split friction clutch brake provides superior performance, enabling rapid cycle times and consistent forging quality.

Another significant feature is the crank toggle mechanism, which allows the slide to dwell at the bottom dead center for approximately 1/18 of a cycle. This design not only enhances forging precision but also minimizes wear and tear on the machine, thereby extending its operational lifespan. The dwell time ensures uniform forging of the metal, resulting in higher quality products with minimal defects.

Additionally, the GK Series is equipped with a highly accurate die height indicator that displays values with an accuracy of 0.01mm. This precision is crucial for maintaining consistent forging depths and ensuring that each component meets exact specifications. The die height indicator, combined with PLC-controlled operations, facilitates real-time adjustments and monitoring, thereby enhancing the overall precision and efficiency of the forging process.

Superior Engineering and Design

GUANGDUAN’s dedication to superior engineering and design is evident in every aspect of the GK Series knuckle joint presses. The use of high-quality materials and robust construction ensures that these presses can endure the rigorous demands of industrial metal forging. The integral and split structure designs not only provide structural integrity but also simplify maintenance and repairs, reducing downtime and enhancing operational continuity.

The PLC-controlled system integrated into the GK Series offers a user-friendly interface with precise control over forging parameters. This automation allows operators to set and monitor various aspects of the forging process, such as pressure, speed, and cycle time, with ease. The intuitive interface enhances operator efficiency and minimizes the likelihood of human error, leading to more consistent and reliable production outcomes.

Aesthetic considerations are also addressed in the GK Series design. The sleek and modern appearance of the machine not only contributes to a professional factory environment but also reflects the advanced technology housed within. The well-organized layout and accessible control panels ensure that operators can easily manage and monitor the forging process, further enhancing the machine’s usability and efficiency.

Extensive Range of Applications

The versatility of the GK Series knuckle joint presses makes them suitable for a broad spectrum of applications across various industries. In the automotive sector, these presses are utilized to manufacture critical components such as crankshafts, gears, and suspension parts, where precision and durability are paramount. The ability to handle high-capacity forging ensures that automotive manufacturers can efficiently meet large-scale production demands.

In the aerospace industry, the GK Series is employed to produce high-strength components that require stringent quality standards and precise forging. The advanced features of these presses, including the accurate die height indicator and PLC control, ensure that each aerospace component meets the exact specifications necessary for safety and performance.

Beyond automotive and aerospace, the GK Series finds applications in construction, machinery manufacturing, and other industrial sectors where robust and reliable forging presses are essential. The capacity to customize the forging presses to meet specific production needs allows manufacturers in diverse fields to leverage the GK Series for their unique applications, ensuring high-quality output and operational efficiency.

Conclusion

Choosing the appropriate Forging Press for Sale is critical for the success and efficiency of any industrial metal manufacturing operation. GUANGDUAN’s array of customized and affordable forging presses, particularly the Knuckle Joint Press GK Series, offers unmatched quality and performance tailored to meet the diverse needs of manufacturers. Whether you aim to enhance your production capabilities with a specialized forging press or seek a cost-effective solution without compromising on quality, GUANGDUAN provides the ideal forging press solutions for every budget.

Investing in a forging press from GUANGDUAN means opting for reliability, precision, and advanced technology that drive industrial excellence. For more information on GUANGDUAN’s forging press offerings and to discover the perfect solution for your metal manufacturing needs, contact GUANGDUAN today and take the next step towards optimizing your manufacturing operations.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us