The Arrival of the 100-Ton Stamping Press For Precision Production

The 100-ton stamping press marks a significant advancement in manufacturing. Designed to handle heavy materials with exceptional precision, it will transform the production process. By boosting both speed and quality, the press enables the creation of more complex parts with greater efficiency. As demand for precision manufacturing rises, this new addition helps companies stay competitive on a global scale. It not only increases production capacity but also reduces costs, unlocking new opportunities across various industries. Let’s dive in!

The Power Behind the Press: What Makes It Special

Explanation of the 100-Ton Capacity and Its Technical Advantages

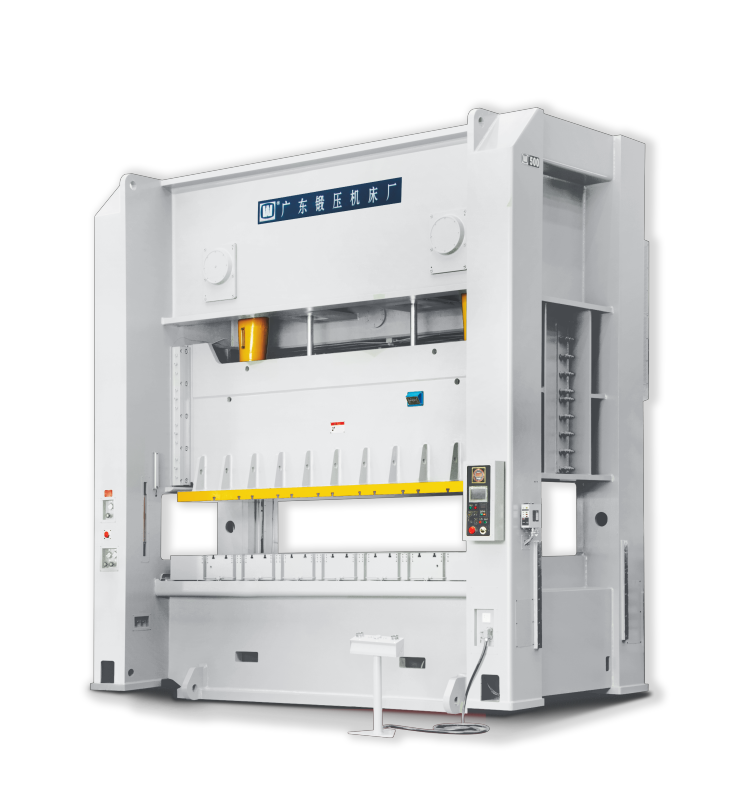

The 100-ton stamping press GD2 is a powerful machine. It can handle heavy materials with ease. The press has a capacity of 100 tons, which makes it ideal for large, complex parts. The main structure of the press is made from high-quality steel plates. These parts are welded together, giving the machine great rigidity. This rigid structure allows the press to perform well under heavy loads. It can produce parts consistently and accurately. The press is built to last and can handle tough tasks with no issues.

How the Press Enhances Accuracy and Efficiency in Production

This press improves both accuracy and efficiency. It uses a two-level gear transmission system. This helps the press operate smoothly and quickly. The slide’s operating strokes are high, which increases production speed. The press has an enlarged interval between the crank and the connecting rod. This feature makes the machine more resistant to unbalanced loads. It also helps the press maintain precision over time. As a result, the press produces high-quality parts quickly and efficiently.

Benefits to Local and Global Industries

Impact on Industries Like Automotive, Aerospace, and Electronics

The GD2 stamping press benefits many industries. It plays a big role in the automotive industry. Educorpus Car manufacturers need precise parts for engines and body structures. The press helps meet these needs. The aerospace industry also relies on this machine. It makes parts for aircraft that require high accuracy and strength. Electronics companies use the press to make small, detailed components for devices like smartphones and computers. The press meets the needs of these industries by producing high-quality parts quickly and at scale.

How the Press Meets Increasing Demand for High-Precision Components

As industries grow, the demand for high-precision parts increases. The 100-ton press helps meet this demand. It can produce small, complex parts with great accuracy. This is important in fields like aerospace, automotive, and electronics, where precision is key. The press makes it possible to meet rising production demands while keeping quality high. It ensures that manufacturers can deliver parts that meet strict standards. This capability will be even more important as technology continues to advance.

Guangduan‘s Cutting-Edge Technology: Features of the New Press

Advanced Technology Integrated into the Press

The new press uses advanced technology. The slide has an eight-surface long-guide system. This helps reduce side force and improves precision. The press can also be fitted with a multi-section air cushion. This cushion is used for multi-station stamping. It also has an upper knockout cylinder for the slide block. These features make the press suitable for metal sheet stamping. The press is ideal for automation industries, such as progressive die and multi-station stamping. The press supports both two-dimensional and three-dimensional servo production line installation. These features allow for better flexibility in production and enable companies to increase output without compromising quality.

How These Innovations Push the Boundaries of What’s Possible in Stamping

The new press offers many innovations. It improves stamping accuracy and efficiency. The use of the eight-surface guide helps the press stay stable during operations. The multi-section air cushion ensures even pressure during stamping. These features allow the press to handle complex tasks with ease. The inclusion of servo production line interfaces makes the press adaptable to future technology needs. The press sets a new standard for stamping machines, pushing the limits of what can be done in this field. It opens up new possibilities for manufacturers to create more complex, precise parts.

Boosting Productivity and Reducing Costs

The Operational Efficiencies Gained Through the Press‘s Capabilities

The new press increases productivity. It operates efficiently, saving time in production. The high-precision design reduces errors and rework. This leads to fewer delays and faster output. The press is designed to perform well under heavy workloads, allowing it to handle large-scale production. With its high operational speed and accuracy, it helps manufacturers produce more in less time.

How It Helps Reduce Material Waste and Manufacturing Downtime

The press also helps reduce material waste. Its precise stamping ability ensures that less material is wasted during production. This lowers costs and improves the overall efficiency of the manufacturing process. The press reduces downtime by working continuously at high speeds. Its reliable performance means fewer interruptions in production, which leads to a more consistent output. By minimizing downtime and waste, the press helps businesses cut operational costs and increase profit margins.

Environmental Considerations and Sustainability

Eco-Friendly Features of the GD2 Stamping Press

The GD2 stamping press is designed with eco-friendly features. It uses less energy compared to older models. The press is built to operate efficiently, minimizing power consumption. Its precise design reduces waste, which helps conserve resources. The press is made from materials that are durable and easy to recycle. This design makes it a more sustainable option for manufacturers who are looking to reduce their environmental footprint.

Its Role in Supporting Sustainable Manufacturing Practices

The GD2 stamping press plays a key role in sustainable manufacturing. Its efficiency helps manufacturers reduce their overall energy use. The reduction of material waste also supports sustainability. By improving production processes, the press helps companies become more environmentally responsible. This machine supports green manufacturing practices, which is important as industries move towards more sustainable production methods. The press enables manufacturers to meet both high production standards and environmental goals.

Upgrade Your Manufacturing with Guangduan‘s GD2 Stamping Press

The GD2 stamping press offers great benefits. It improves accuracy and boosts production speed. This machine helps reduce waste and cuts costs. It is eco-friendly and supports sustainable practices. It can meet the growing demands for high-quality, precision parts. If you want to stay competitive, invest in the GD2 stamping press today. Take the next step towards better production efficiency and reduced environmental impact. Make your manufacturing process more effective and cost-efficient. Upgrade now and lead the way in innovation!

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us